Air Conditioning in Factories: the Future of Many Industries?

In the era of climate change, summers are warmer and more humid than ever. Heat waves are frequent, and periods of high heat drag on. This raises major issues concerning the general ventilation of factories, where the temperature rises dangerously.

Although the mercury has currently dropped, this is the ideal time to find solutions to this problem, especially in a context where delivery times are expected to increase. Find out why air conditioning is now a favourable option in an industrial setting.

Heat and Humidity: Critical Structural Consequences They Have

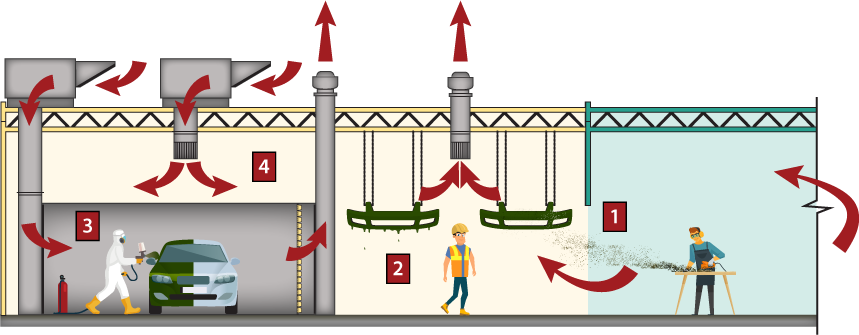

With these heat peaks becoming the norm, the ventilation or simply opening garage doors is no longer enough to cool the factory space during the summer. In many cases, the fresh air intake units installed on the roof draw in air that can easily reach 40°C (104°F)! (Figure 1 - NO 4)

Imagine for a moment a confined work area, like a painting chamber, with its own dedicated ventilation system for generating laminar flow bringing in 100% fresh air on one side and 100% exhaust on the other. Since solvents and volatile organic compounds (VOC) are found in these areas, it is mandatory for workers to wear personal protective respiratory equipment.

Figure 1

In the middle of a heat wave, the ventilation directly draws in stifling air from the outside. This heat is exacerbated by respiratory equipment that increases the discomfort level of the confined painters who are suffocating (Figure 1 - NO 3). Because of the high humidity of the air drawn in, paint dripping could also form on the parts, and drying problems could occur, impacting the quality of the product (Figure 1 - NO 2).

In general, if it’s imperative to ventilate that chamber properly, in the context of extreme heat, cooling the incoming air also becomes necessary! Last summer, some of our clients were forced to suspend production for a full month due to the stifling atmosphere in their facilities.

In addition, manufacturing processes are often equipped with air extractors to decontaminate their environment, which results in negative pressurization of their workspace. As a result, air movement can occur from one department to another, generating risks of cross-contamination. Think of a cutting department whose dust residues are likely to contaminate parts drying in an adjacent paint department (Figure 1 - NO 1).

To prevent these problems, some will want to add a cooling coil to the fresh air intake units. However, since they are mostly direct-fired, an interlocking device with exhaust mechanisms is required in order to prevent carbon monoxide (CO) from building up and thus meet the standards of the Régie du bâtiment regarding air exchange in a work area. Result: the air that is cooled just a few degrees will need to be exhausted immediately. A waste of energy and money that could be prevented.

Is Air Conditioning a Cost-effective Solution? Absolutely!

Until recently, cooling industrial work areas was unthinkable because of the energy cost involved and the CAPEX for expenses associated with facility maintenance or improvements. With the new paradigm resulting from climate change, the lost productivity and performance caused by extended periods of high heat and humidity are reversing this trend.

Therefore, it becomes more advantageous to invest in air conditioning for the facility to continue production, reduce losses and quality problems, and prevent delays. This is true, even though the solution is more expensive at first and air conditioners use approximately 15% more natural gas to heat in the winter (since they are indirect-fired)!

Let’s take the example of the painting chamber. Replacing direct-fired air intake units with air conditioners offers a range of benefits!

A Close Look at the Tangible Benefits of Air Conditioning

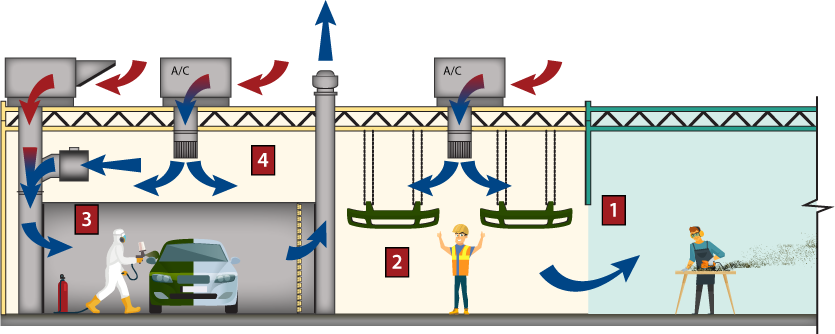

Figure 2

- Preventing cross-contamination through positive pressurization of the space. Since air-conditioning units are indirect-fired, they don’t necessarily need exhaust mechanisms – since there is no CO in the airflow. The cooled air therefore stays within the facility.

This allows positive pressurization of the work area, reducing the risk of cross-contamination with, for example, the exterior of the painting chamber or adjacent cutting departments. These could generate highly explosive aluminum dust that, if deposited on items that are freshly painted or waiting to be painted, would make them unusable. This leads to the next point! - Preventing loss of materials and production shutdowns. Extreme environmental conditions can jeopardize the production of components requiring high precision. The physical integrity of softwood lumber is partly influenced by the high relative humidity of the air. Its size would therefore not be the same as when it was in the factory. Once it reaches its destination, the part could be too small or twisted.

Humidity and heat affect a number of other materials and processes, hence the decision by some factories to stop production rather than lose materials. - Cooling the fresh air drawn in with a dilution solution. Going back to the painting chamber: since it must remain in place, its cross-barred intake and exhaust system is always bringing a stream of refreshed air into the chamber.

To improve this configuration, the stream from the fresh-air intake unit and the air-conditioned ambient air coming from the department can be routed to a mixing box. The dilution of these two sources thus introduces into the painting chamber an air stream whose temperature and humidity level meets parameters that ensure continuity of operations. - Ensuring safe Working conditions for the workforce. Air conditioning greatly improves employees’ comfort. Painters, welders, sanders and other workers will be able to work in a confined or unconfined environment where the humidity and temperature levels are tolerable.

Our Advice? Don’t Wait Until Next Year!

Despite the current return to a more normal operating situation, periods of extreme heat are not going to decrease. Right now, delivery times for air conditioning units are at least 6 months.

To choose the right air-conditioning option, turn to versatile experts who can support you with your projects from A to Z. In addition to offering tailor-made solutions and a turnkey service, we can also do the following:

- Visit your facilities

- Your statement of specific needs

- Analyze your options through our simulation labs

- Load calculations, impacts on production and existing ventilation

- Develop customized filtration systems

- Search for possible grants

- Install and commission ventilation and air-conditioning systems

This is the advantage of doing business with general contractors who particularly specialize in air management, ventilation, and industrial air conditioning. It’s never too soon to take action: contact us now!

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?