Foray Into The World Of Dust Control

Dust control is a field of expertise unto itself. Separation techniques, angle of repose of particles, anti-explosion protection... multiple aspects come into play when it comes to sanitizing the air in an industrial space. If you work the manufacturing, mining or other industry, this aspect of the work environment is undoubtedly of concern to a number of your departments. And for good reason! Poor air quality management can jeopardize the workers’ health as well as cause premature wear of some equipment.

Need a little more information on this subject? Here is an overview.

First, it’s important to know that there are different types of aerosols to filter out. Gases represent the first category. Made up of tiny submicronic particles, they usually come from industrial smoke resulting, for example, from a welding/soldering phase. The second category of aerosols includes particles, debris that is easier to trap, given their size. These particles originate from mechanical processes like grinding, sanding or polishing. The term “load” refers to the concentration of particulate matter per unit of air volume to be treated.

Aerosol separation techniques

There are three main dust removal methods.

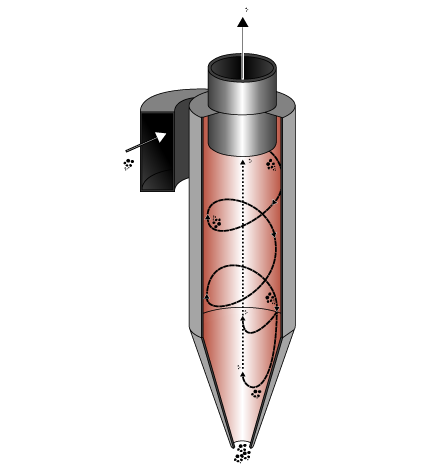

Centrifugation

Effective only for large particles, this technique involves spinning air around inside a cylindrical chamber. By means of the cyclonic effect, the dust particles suspended in the air are subjected to centrifugal force and, being heavier than air, are directed towards the walls of the dust collector. By means of gravity, they then fall towards the outlet. Dust collectors using this technique are cyclone dust collectors.

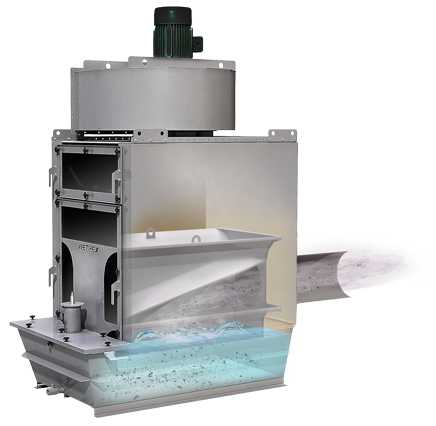

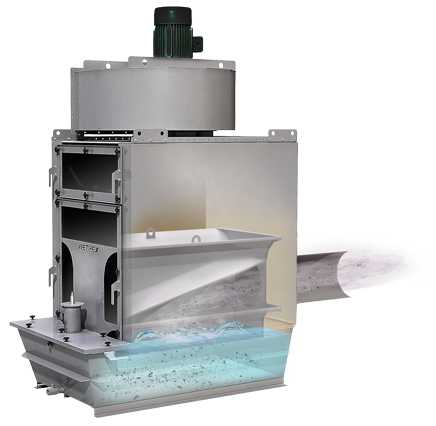

Immersion

As for the web scrubber system, it sanitizes by mixing contaminated air with water. Particle separation is achieved by the creation of a zone of violent turbulence, thus forcing interaction between the water and the contaminated air. Once they are in the water, the particles settle to the bottom of the basin. Wet dust collector are the pieces of equipment used to trap the dust particles in water.

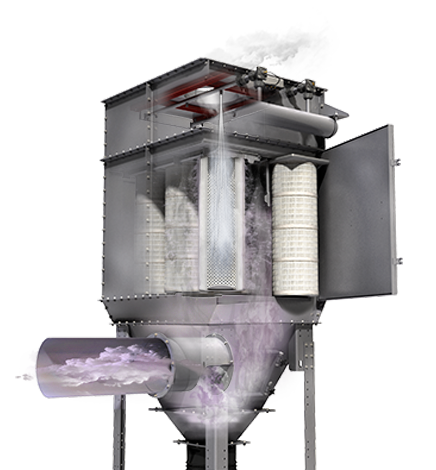

Filtration

A number of filtration media can be used in a dust removal process. To select them, the factors to be considered are: air temperature (average and peak), humidity, exposure to chemicals, characteristics of the dust, and effectiveness in terms of load reduction. In all cases, flushing mechanisms will have to be put in place to prevent clogging, while ensuring smooth air flow and good filtration performance. Three dust collection systems make use of use this particle separation technique: baghouse systems, cartridge systems and shaker dust collectors.

Proper system maintenance is a must

To prevent the dust collector from wearing out prematurely, it is essential to take a methodical approach to maintaining the system and changing the filters. The pressure gauge tubes must also be cleaned regularly so that the readings they give are accurate. Lastly, to prevent compressed air leaks, the diaphragm valve gaskets need to be replaced at an established frequency. In the maintenance schedule, some tasks are monthly and others are annual. A system re-balancing should also be done every three years.

As you can see, dust removal for air-sanitizing purposes involves a number of highly technical aspects. To delve even deeper, register your teams for our training sessions ! Your engineers will even be able to compile recognized hours as part of their mandatory continuing education; find out more.

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?