Mobility And Welding Fume Extraction In The Work Place

Extracting welding fumes can be a real headache when your machine shop has large work areas where the workers must continually move around to perform their tasks. However, there is a simple, effective solution for maintaining the air quality in your work environment, yet without breaking the bank.

The challenge of filtering large spaces without inconveniencing the workers

The classic filtration method of installing extraction points connected to a dust collector via a system of ducts can sometimes come up against certain obstacles when being put in place.

Obstacle no. 1: Travelling crane

The clearance needed for the proper operation of a travelling crane complicates the installation of ductwork, especially when you have to extract airborne emissions that are generated in the centre of the work area.

Obstacle no. 2: Reach of the extraction arm

Extraction arms can be installed that have ducts along the walls. Unfortunately, that type of installation can become very restrictive because the reach and the angle of coverage limit the worker to roughly 25 ft. from the wall.

Obstacle no. 3: Existing environment already overloaded

Too often, existing manufacturing plants are full of various accessories already in place, such as light fixtures, tool, machines, air supply and return systems, to say nothing of the various types of industrial equipment there. In a setting like that, adding a dust-removal system becomes a real feat.

A review of some solutions already touched on

In an earlier article, we already covered the topic of the different at-source capture solutions for welding fumes. Those solutions are particularly recommended when you are dealing with hexavalent chromium emissions.

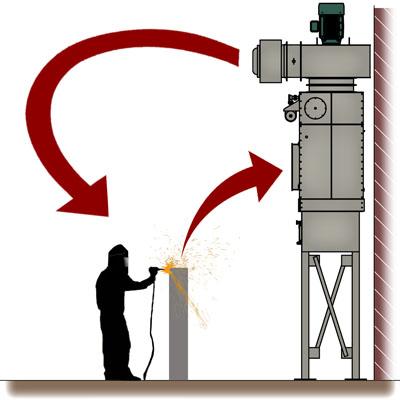

A portable dust collector is, by and large, a solution with limitations. It can be difficult to use a device of this sort when the welders have to work on very large-scale parts (naval industry, for example). Also, the weight of it limits its movements on the plant floor. Which limits as well its use in the context of machining components that are up high. Moreover, this type of equipment can simultaneously cover the activities of only two workers, at most.

The compact intake incorporated into the welding nozzle is a very promising solution because it enables the workers to keep the same work habits. However, the welding nozzle becomes enlarged and considerably heavier. Besides, the horsepower required to effectively carrying out the suction is considerable due to its restrictive nature.

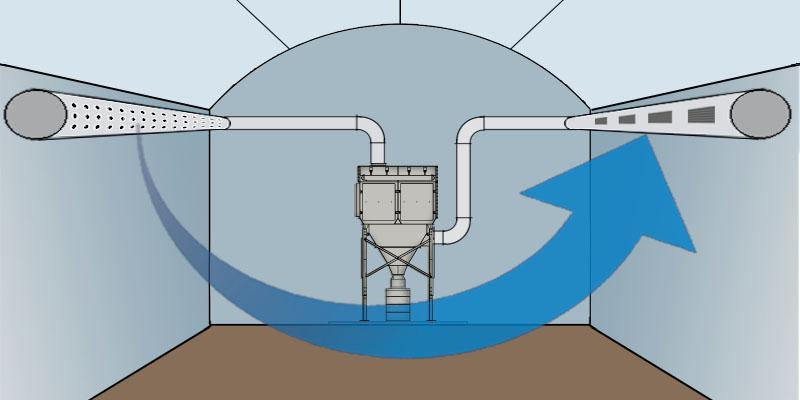

Cross-draft filtration is one of the other filtration strategies touched on in a previous article. This method involves maximizing the number of air exchanges within a work area via extraction, filtration and recirculation of an airflow by means of a dust collector connected to two perforated pipes.

The downfall of ambient systems is that large amount of air are required to filter the pollutants, unfortunately resulting in a very expensive solution. However, our research team has managed to perfect a new product that improves all aspects of the original design.

Here is the new solution for accomplishing cross-draft filtration:

The laminar cross-draft filtration system

This filtration equipment is relatively recent among Airex Industries’ product line. However, it is worth paying special attention to it because, in addition to being amazingly simple, its design is surprisingly effective, all at a very affordable price.

Unique design

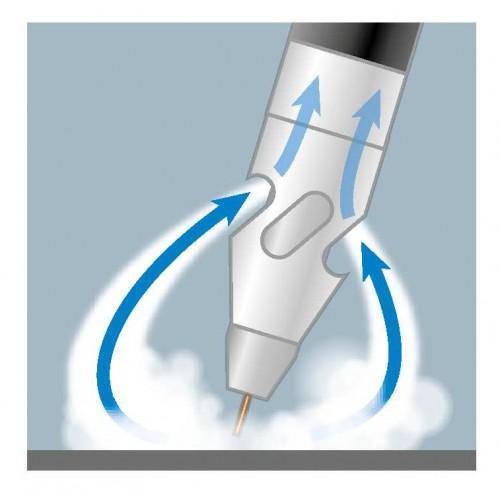

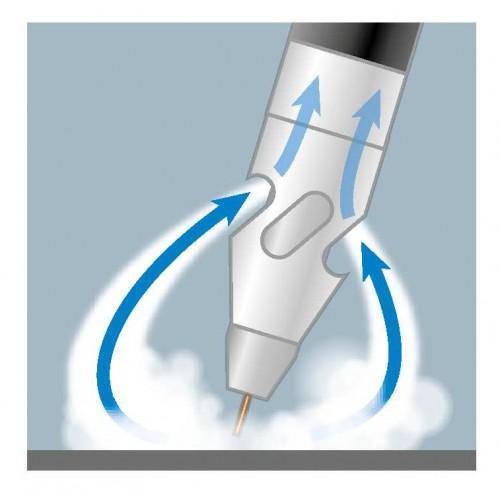

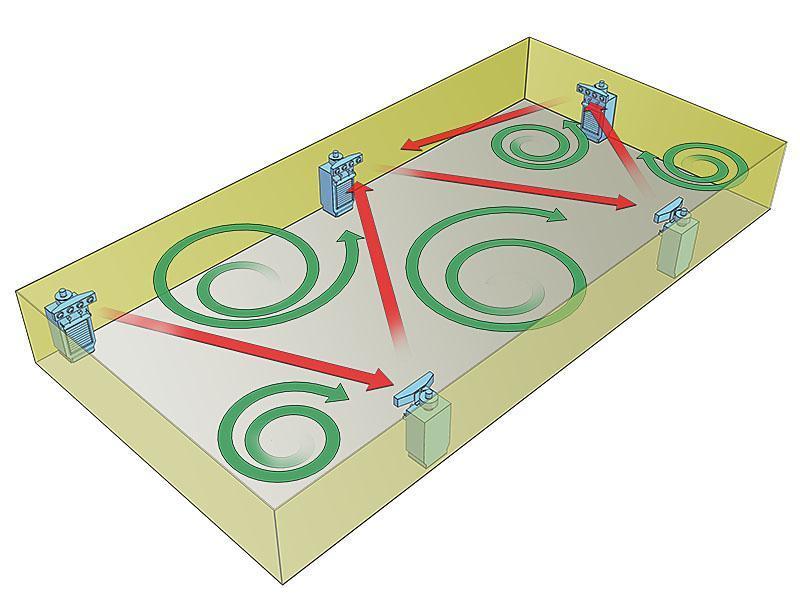

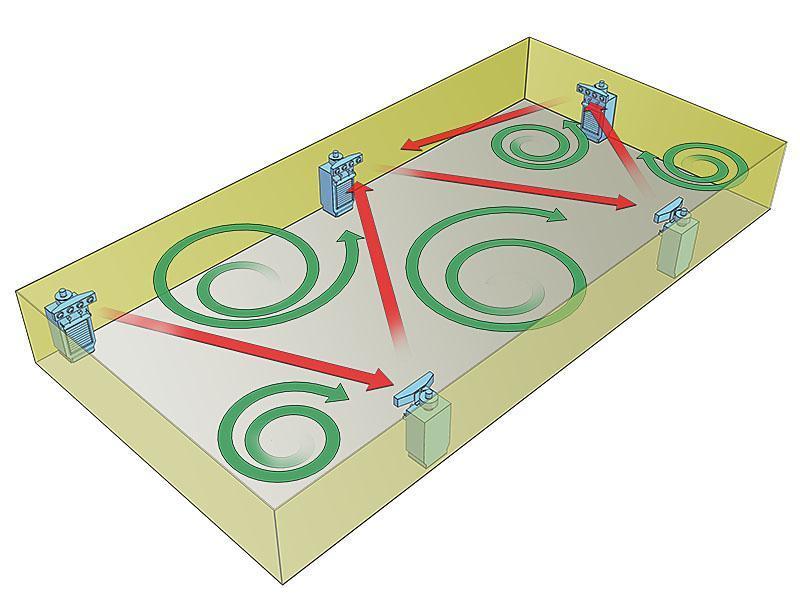

A set of nozzles installed at the top of the machine directs an airflow toward the welding emissions. In the lower section of the machine, a louvre fitted with filtration cartridges takes in the ambient air, decontaminates it and then blows it out again through the nozzles in the upper section.

In other words, this filtration technique swirls the ambient air and purifies the work environment without changing the workers’ work habits. In addition, the high-velocity nozzles make it possible to ventilate hard-to-reach places over long distances without ductwork.

This type of machine can also be paired with others in order to cover very large work areas. When placed at the periphery, the various units will create swirls of air so that the airflow driven by some of them can be taken in by others. This synergy arising from combining multiple units will ensure an air quality, at the same time reducing the risks of certain occupational respiratory diseases.

To learn more about the laminar cross-draft filtration system

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?