Industrial Laundry Dryer Heat Recovery Unit

Lintx

The LintX is designed to recover the heat energy from the exhaust air from industrials dryers which was until now rejected to the atmosphere without possibility of recovery due to the presence of lint.

Drying remains one of the most energy consuming processes in a industrial laundry, and we respond with a new, innovative heat recovery unit. The LintX feature a simple and efficient air-to-air plate heat exchanger and a patent-pending self-cleaning filter section to overcome the risk of heat exchanger clogging.

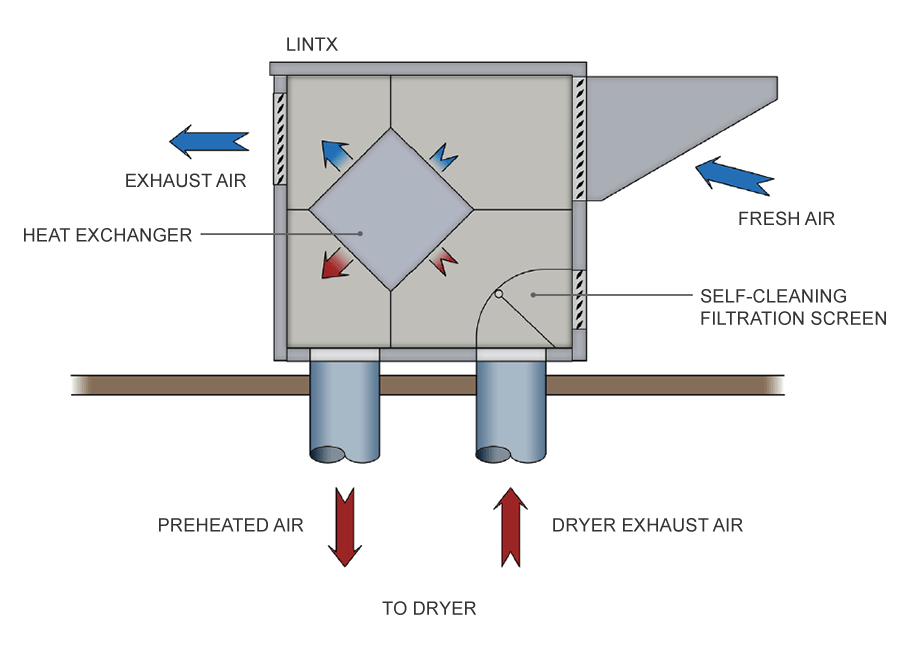

How it Work

A patent-pending self-cleaning filter removes residual lint from the exhaust air that could affect the heat exchanger’s performance. The sensible heat from the exhaust air flowing through one side of the exchanger is transferred to the cold air flowing through the other.

Features

- Removable air-to-air plate heat exchanger

- Aluminium construction

- Corrosion-resistant

- Cross airflow pattern

- Low static pressure

- No moving parts

- Patent-pending self-cleaning filter

- Low maintenance and long-lasting equipment

- Easy installation

Benefits

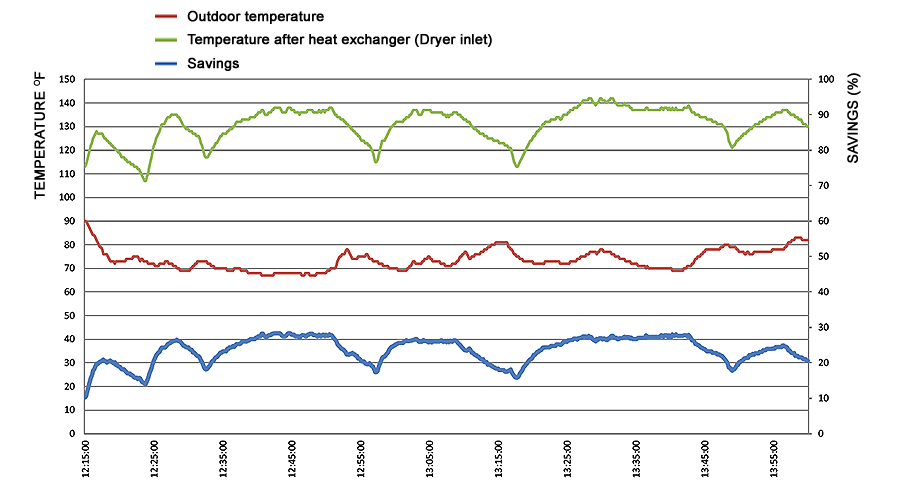

- Up to 30 % reduction on energy consumption

- Reduced drying time

- Cost competitive – 2 years payback and less

Selection Criteria

- Exhaust air flow

- Exhaust air temperature and humidity

- Percentage of recirculated air flow

- Available Electrical voltage

IMPROVE AIR HANDLING OF YOUR FACILITIES

I WANT TO KNOW MORE

![]()

Savings

Standard Characteristics

- Easy access for maintenance

- Non clogging heat exchanger design

- Centralized intelligent control system

- Self-cleaning filter

Optional Features

- Central lint dust collector

- RHX special humidity sensor for optimum energy recovery

- Custom designed control interface to link to existing dryer’s control panel/board

- Data acquisition device for optimum control program

- Roof curb

Lintx Flowsheet

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?