Relative Humidity Sensor

RHX

This sensor measures in real time the relative humidity of air at high temperature in a contaminated environment.

The new RHX probe (patent pending) has been developed in partnership with FPInnovations-Forintek. The probe can measure continuously and in real time the wet bulb temperature of a high temperature gas from a contaminated environment in an industrial process. With its unique electro-mechanical assembly, Airex Industries has managed to offset the restrictive constraints of clogging of highly contaminated particles and unsaturated steam.`

How it Work

The RHX high temperature relative humidity sensor possesses a simple and sturdy mechanism which resists corrosion in extreme industrial conditions. The match-up of this mechanism to a sophisticated control logic provides the RHX sensor with a flexible and precise calibration capacity which adapts itself to any drying conditions.

Detailed operation

- The hot and wet process gases are read by a high precision industrial thermocouple sensor.

- The unique electro-mechanical system retracts the probe and cleans it to remove any particulate deposit.

- The probe is then introduced into the contaminated air for a subsequent reading of wet bulb.

- The control logic searches the data corresponding to the wet bulb and produces a graph of the average reading over time.

- All operating parameters are programmable in terms of process.

Advantages

- Continuously measures the relative humidity of process air.

- Allows to adjust the burner capacity of an industrial dryer for optimization of the fuel consumption in real-time.

- Allows to minimize the fresh air intake of an industrial drying process according to atmospheric changes.

- Maintains product consistency even with external variations.

- Significantly reduces the emission of greenhouse gases (GHG).

- Does not affect operating conditions.

- Requires little maintenance since a self – cleaning system is integrated in the device.

PARTICIPATE IN A LUNCH AND LEARN OFFERED BY AIREX INDUSTRIES

SUBSCRIBE NOW

![]()

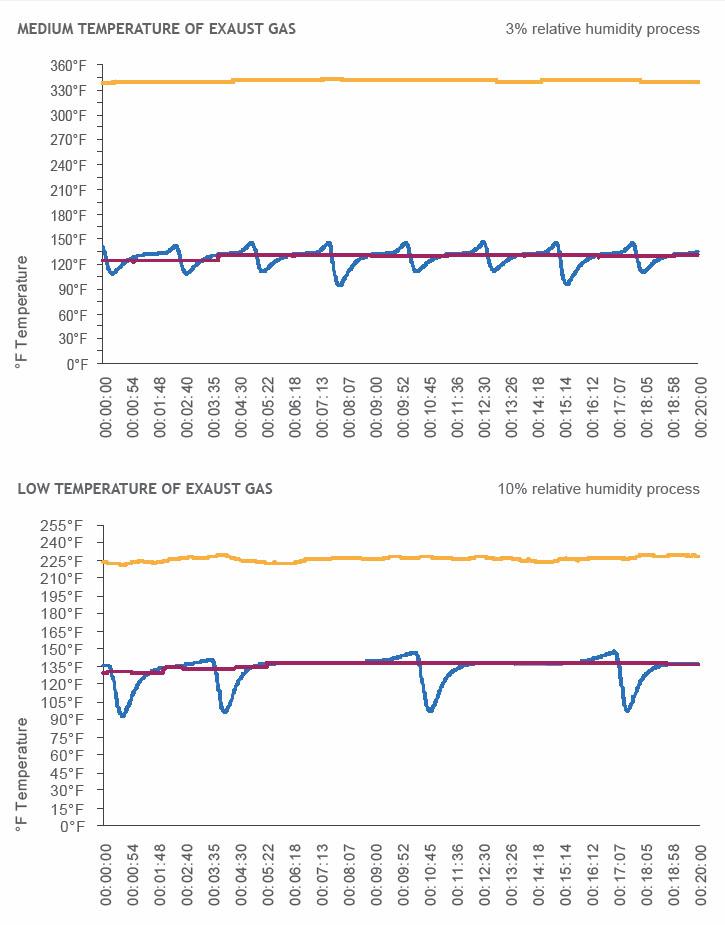

Gas temperature analyzing table

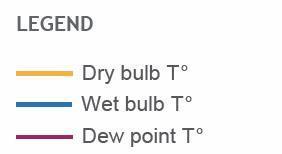

Examination of the wet bulb temperature curve allows to observe and to separate each of the cycles done by the probe. Radical decreasing of wet temperature shows that the probe is completing a cleaning and re-humidifying sequence. Reintroduction of the probe in the hot conduct can be detected when the temperature is going up again.

Real wet bulb temperature is precise at the stabilization of the curve, before the probe becomes completely dry, before temperature increases again and that the cleaning sequence starts a new cycle. Probe controller is programmed to calculate and targeting each of these different zones on the curve to optimize the number of cycle and to have the more precise value possible.

Calibration temperature on the graph represents the stabilized value for the wet bulb. It is this value that is compared to the dry bulb reading to calculate relative humidity and dew point. Higher temperatures of hot gazes will result of increasing the frequency of the probe cycle

|

||||

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?