Cartridge Downdraft Table

DDT Series

The self cleaning cartridge downdraft table helps eliminate dust, smoke and other airborne pollutants before reaching the workers breathing zone.

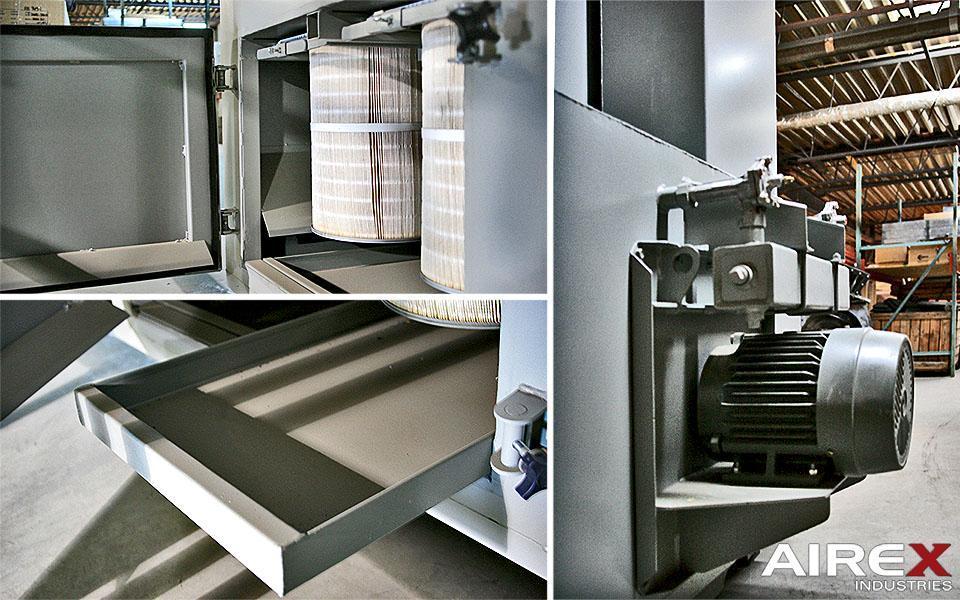

Cartridge downdraft table is designed for industrial applications, the built in motor/blower and reverse pulse self cleaning requires virtually no maintenance while prolonging filter life and units efficiency. This unit complies with environmental clean air regulations.

How it Works

The work surface of the table uses a high face velocity of downward air to pull debris and pollutants away from the worker and towards a set of highly efficient filters. The air is then filtered and returned to the shop. The self cleaning system can then be activated automatically or manually, using a blast of compressed air in the reverse direction to dislodge the debris. The solids are then collected in a dust drawer. Custom sizes are available upon request.

Front or side filter access, deep dust trays, optional casters for ease of movement, multiple grating options, as well as different interchangeable top sections allows the cartridges downdraft table to be tailored, customized to your/any/very specific needs.

PARTICIPATE IN A LUNCH AND LEARN OFFERED BY AIREX INDUSTRIES

SUBSCRIBE NOW

![]()

Standard Characteristics

- Complies with clean air regulations

- High efficiency filtration 99% @ 1 micron

- Non-abrasive grated surface or perforated plate

- Cam shaft cartridge seal mechanism and side access door (no tools required)

- Self-cleaning reverse pulse system

- 12 gauge metal construction

- Spark trap/ baffle tray

- Fire retardant cartridges

Options

- Dual workstation enclosure

- Includes side panels, middle separator panels and top panel

- Plexiglass available

- Backdraft hood

- Light kit

- Plexiglass

- Side and back walls

- Hinged sides

- Light kit

- Middle separator

- Plexiglass available

- PVC matting

- Aluminium / Fiberglass grating / Steel bar grating 2” high

- Metal mesh prefilters

- Grouding Lug

- Extended 12” overhang

- Activated carbon granules in perforated metal canisters (Slides inside filter cartridges)

- Filter cartridge options

- Spunbond polyester cartridges

- Additional cartridges

- H.E.P.A filter

- Stack silencer

- Casters

- Minihelic gauge

Selection Criteria

- Type of dust

- Dust concentrations

- Process conditions:

- Temperature

- Humidity

- Corrosive agent avantages

- Dew point

- Physical constraints

- Disposal method

Applications

- Buffing

- Grinding

- Welding

- Powder Mixing

- Sanding

- Deburring

- Soldering

- Utility table

- Spray painting

- Odour control

- Plasma cutting

Advantages

Vertical Cartridge Design

Due to its vertical cartridge design, the DDT series of cartridges downdraft table, unlike most of its competitors, does not require any semi circle baffles to prevent the unnecessary accumulation of dust on any particular side of the cartridges. Dust particles are spread and filtered equally on all sides of the media; unlike the horizontal cartridge design where you can lose up to 30% of the effective filtering surface, Airex Industries’ DDT series of cartridges downdraft tablemaintain a 100% of its filtration area all the time.

Fast, Simple and Safe Cartridge Replacement

- The entire replacement of the set of cartridges is done from outside the downdraft table and requires no tools.

- The cartridge is provided with a rectangular adapter that simplifies the manipulation of the cartridge, and eliminates installation errors.

Models

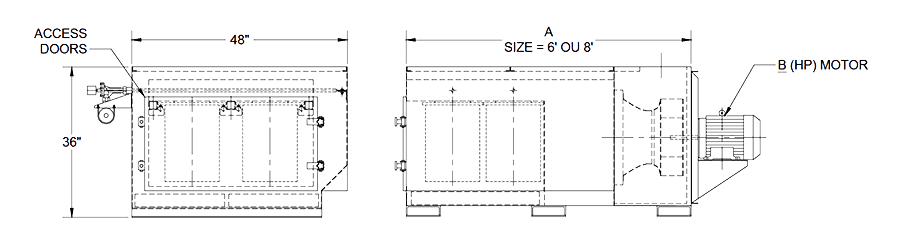

There are two base models for the DDT series: the DDT 75 and the DDT 100. Custom cartridges downdraft table are not an issue and will most probably be better fitted for your particular needs.

Specifications

| Model | DDT 10 | DDT 15 |

| CFM | 3 600 | 4 500 |

| Face Velocity (F.P.M.) | 225 | 187.5 |

| Motor | 10 HP | 15 HP |

| Fan Type | BI Wheel | BI Wheel |

| Self Cleaning | Reverse pulse Air | Reverse Pulse Air |

| Dimensions | (A) 6’ x 4’ x 3’ | (A) 8’ x 4’ x 3’ |

| Weight | 550 lbs approx. | 675 lbs approx. |

| Work Surface | 4’ x 4’ Steel Grating | 6’ x 4’ Steel Grating |

| Filters | Cartridges | Cartridges |

| Construction | 12-14 Gauge | 12-14 Gauge |

| Dust Drawer(s) Capacity | 2.5 ft.³ | 3.8 ft.³ |

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?