Airex Industries designs and manufactures a wide range of air cleaning and pollution control products for industrial manufacturing. Discover our solutions.

Products

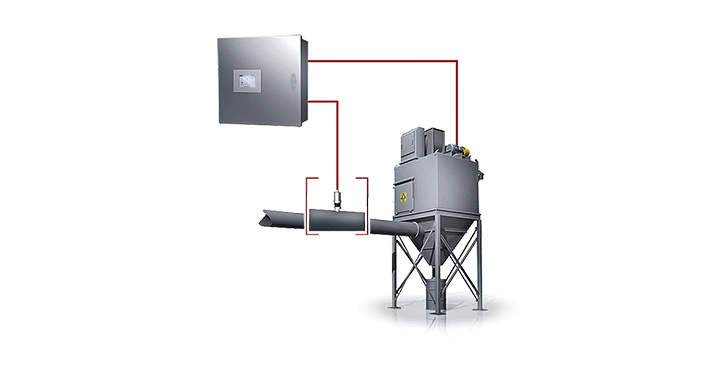

DUST COLLECTORS

Airex Industries produces a wide range of baghouse, cartridge, cyclone, and wet dust collectors for virtually any manufacturing application. Discover our solutions.

EXPLORE SOLUTIONSAIR HANDLING UNITS

Airex Industries Air Handling Units are engineered for superior air quality and energy efficiency. Experience reliable, cost-effective performance that improves your industrial environment.

EXPLORE SOLUTIONSINDUSTRIAL OVENS

Industrial ovens are used for a variety of industrial applications such as curing, baking, or drying components, parts, and/or even final products. Our industrial ovens meet the requirements of NFPA86.

EXPLORE SOLUTIONSDUST COLLECTOR ACCESSORIES

Enhance your dust collection system with our top-quality accessories, including dampers, capture arms, and valves. Improve efficiency and air quality today.

EXPLORE SOLUTIONSENERGY RECOVERY SOLUTIONS

Airex Industries designs and manufactures a wide range of energy recovery solutions for reduced energy costs and a greener environment.

EXPLORE SOLUTIONSENVIRONMENTAL CONTROL SOLUTIONS

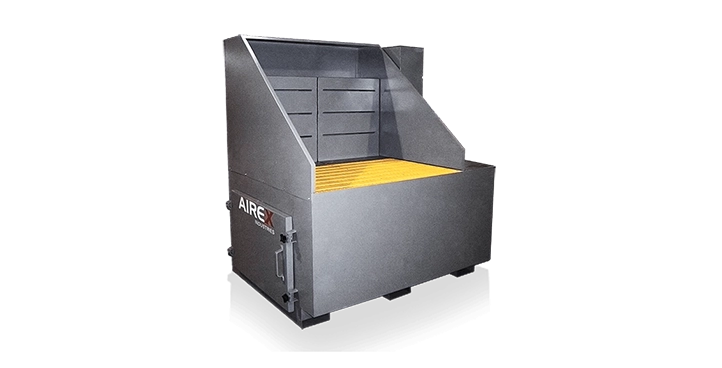

Airex Industries produces a wide range of air purification systems, downdraft tables, and portable units for common manufacturing applications.

EXPLORE SOLUTIONSINDUSTRIAL BLOWERS

Airex Industries designs and manufactures various types of industrial blowers for common industrial air cleaning systems.

EXPLORE SOLUTIONS