Integrated Energy Recovery Make-Up Air Units

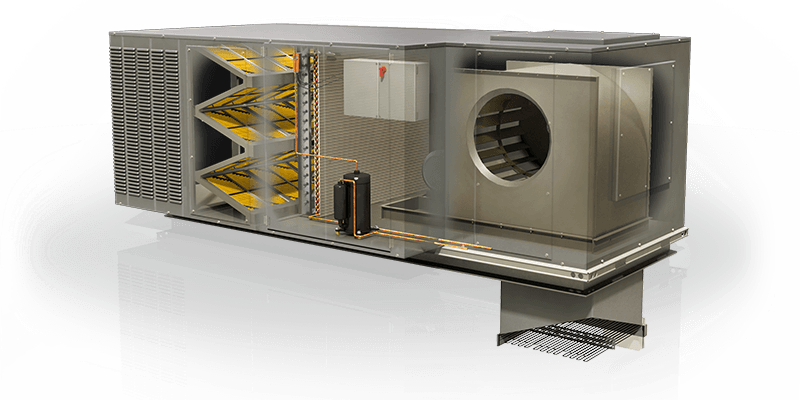

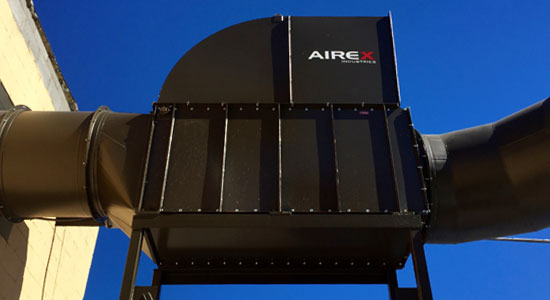

PowerFX

The PowerFX system is designed to recover the available energy from a hot air vent duct of a building. It uses this energy to preheat the fresh air of an Airex AMX Series air make-up, or any other air make-up unit.

The lack of fresh air can be a problem in an industrial building. Air make-up units, such as the AMX, are installed in these buildings to solve this problem. However, in situations that require a large volume of fresh air, these units can become energy-consuming, especially if they are used to heat the building. With the PowerFX, the exhaust air energy released to the atmosphere can be recovered. This energy is then returned to the air make-up unit.

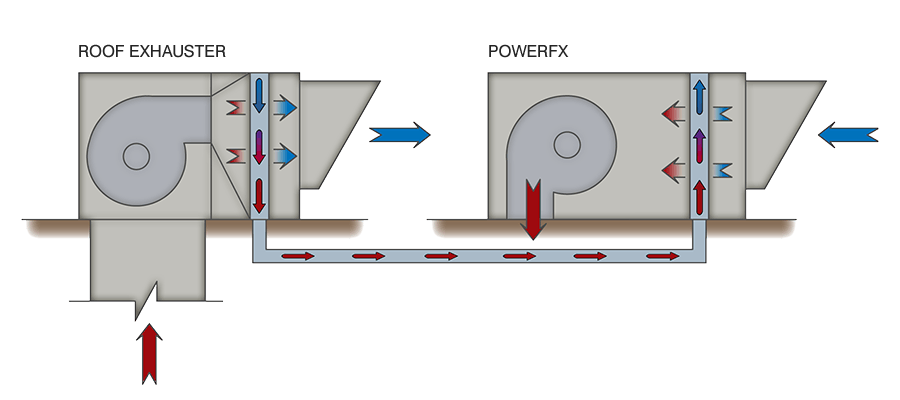

How it Work

Firstly, an energy recovery coil should be installed in the air evacuation duct of the building, ideally of similar capacity (same air flow). The coil absorbs energy that would otherwise be released to the atmosphere. A refrigerant loop carries the captured energy to a compressor which is installed in the air make-up unit. The compressor operates under the principle of heat pumps. It releases a high temperature fluid from a low temperature source. This high temperature fluid is used to preheat the fresh air before it is fed into the building.

Territory served

WE SERVE THE GREATER MONTREAL AREA, INCLUDING THE NORTH AND SOUTH SHORES.

![]()

Standard Characteristics

- Horizontal roof exhauster

- Direct expansion energy recovery thermal coil

- Direct expansion heating coil

- Refrigerant loop

- Heat pump type compressor

- Multistage compressor to avoid frequent starts / stops.

- Reversible valve to enable dehumidification in summer

- CSA approved Control Panel

- Electric heating coil (optional)

Selection Criteria

- Air make-up system air flow

- Air flow from the exhaust related to the PowerFX

- total heating capacity Percentage to be supported by a PowerFX

Applications

- Commercial kitchens

- Laboratories

- Indoor parkings

- Mechanical workshops

- Offices

- Schools

- Industrial buildings

- Residential buildings

Advantages

- Energy recovery from hot air exhausts.

- Decrease in electric peak for electric air make-up.

- Greenhouse gases emissions decrease for natural gas air stabilizer unit (direct or indirect fire).

- Heating costs reduced by over 60%.

- the reversible valve allows to cool and dehumidify the fresh air in summer .

- Increase of the compressor efficiency with an outdoor air temperature decrease, unlike other typical heat pumps applications.

- Installation does not require additional ductwork.

- AMX air make-up units already have the physical characteristics to easily accommodate a PowerFX system.

- The PowerFX system is factory pre-assembled for easy and fast installation in case of existing air make-up units.

- The PowerFX system can be connected to a thermal storage bank.

Specifications

|

||||||||||||||||||

|

|||||||||||||||||||||||||||

* The compressor's additional consumption is included

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?