Preventing Combustible Metal Dust Explosions - Part 2

NFPA 484 addresses combustible metals. The standard provides guidance for prevention as well as recommended practices for the safe management of highly explosive metallic materials generated at different processing steps. Before we explore preventive measures, let us first correctly identify the highly combustible metal.

WOULD YOU RECOGNIZE a highly explosive metal ?

Several metals react violently, especially particulate metal fines under 420 microns. They may appear as powder, dust or fumes. Such metals are used mainly in the transportation industry (that include, for example, aeronautics and automobiles). Although there are few manufacturing facilities of this type, technological advancements requiring high-tech metals are on the rise. Indeed, the need for machined composites incorporating highly combustible metals will substantially increase in the years to come. Here is a listing of highly explosive metals most commonly used in industry.

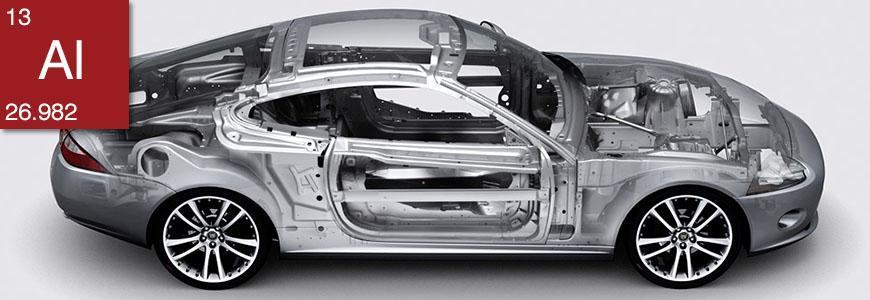

Aluminum

Low density, malleable and resistant to corrosion. Aluminum is the most abundant metal in the earth’s crust and second to iron as the most commonly used metal. Its multiple characteristics and versatility make it difficult to list the number of applications that employ aluminum in their manufacturing process. Toxic fumes released during the transformation process expose workplace personnel to pulmonary infections that may lead to aluminum pneumoconiosis. Welders inhaling aluminum fumes are particularly at risk. Aluminum powder is pyrophoric. In addition, aluminum reacts with water to give aluminum hydroxide and hydrogen gas, thereby contributing to a potentially explosive environment.

Magnesium

Malleable and resistant to corrosion, magnesium is one-third less dense than aluminum. It is the fifth most abundant metal in the earth’s crust. It is often alloyed with aluminum, particularly in aerospace applications. Magnesium in the form of powder reacts exothermically, which explains why it is also employed as a reagent in chemical and pharmaceutical industries. Inhalation of magnesium oxide fumes can cause metal fume fever; respiratory tract irritation with accompanying cough and fever may lead to chronic illness.

Titanium

The seventh-most abundant metal, titanium offers remarkably low density, high ductility, and excellent resistance to wear, corrosion and temperature extremes. It is biocompatible and as such most often found in medical prostheses. Titanium is used in a variety of applications such as in aerospace (ex. : turbine powered aircraft), automobile (ex. : rods, springs, valves), military (ex.: shielding), etc. Five percent of the mineral mined across the globe is refined as a metal. The remainder is transformed to titanium dioxide TiO2 for the production of white pigments typically found in paint, paper, plastic, rubber and various other products. When powdered, titanium poses a significant fire hazard. Dust inhalation may lead to respiratory difficulties with accompanying cough and chest pains. Exposure to dust may irritate the skin and eyes.

Niobium

Largely used as an ingredient in special steels, niobium improves material properties, such as mechanical strength and toughness while maintaining ductility. It is used to produce super alloys for applications in the automotive, aeronautic, military, medical and petrochemical industries, such as pipelines, bridges, nuclear reactors, super magnets and welding rods, to name just these few. As with the other metals described above, niobium powder represents a potential fire and explosion hazard. Inhalation of the fine dust particulate is hazardous to worker health since the metal is absorbed by the organism with a tendency to accumulate in bone tissue. This interferes with calcium as an activator of enzyme systems. It also causes ocular and skin irritation.

Tantalum

Closely related to niobium, the two metals were at first considered the same element. Tantalum is corrosion and heat resistant, making it an ideal candidate for the manufacture of capacitors. It is also found in cell phones, computer parts as well as high-tech electronic automobile gadgets, now highly sought-after features in motor vehicles. Tantalum is also employed in the manufacture of super alloys (in aeronautics), in the chemical industry, in the manufacture of surgical instruments and implants (since it is does not react with bodily fluids), in optics and to filter X-rays. Tantalum powder is pyrophoric and inhalation of dust detrimental to worker health. The fine particulate will irritate mucous membranes, skin and eyes.

Zirconium

The metal withstands corrosion and chemical attack, either acid or alkali-based solutions, making it a well sought-after raw material for the chemical industry, namely in the manufacture of ceramic and refractory products. It is also found in thermal barrier coatings (TBC) of jet engine parts and is a very desirable construction material for nuclear reactors because it is highly transparent to neutrons. Care must be taken since zirconium powder, dust or flakes in contact with air or an oxidant is particularly unstable, pyrophoric and highly explosive. At high temperatures, the metal reacts with water and generates hydrogen gas. Zirconium exhibits weak systemic toxicity. Zirconium dioxide, on the other hand, is a known irritant for the skin and respiratory tract, which (if untreated) may lead to pulmonary fibrosis and possibly emphysema. Skin granulomas have been observed on certain workers exposed to zirconium dioxide.

Next step

Now that we have determined highly explosive metal types and are aware of related hazards, the next step is to recognize the risk within metal processing plants. We will address this issue in our next article. Until then, the best advice to remember is to stay alert when you are in the presence of fine metal particles which emanate from industrial processes.

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?