Doctor, my dust collection system isn’t working. What can I do?

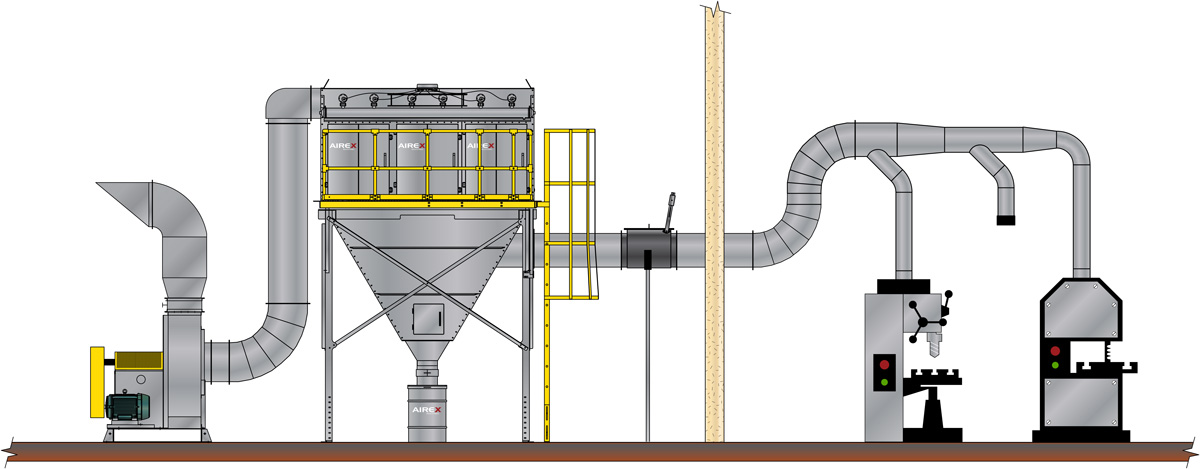

You purchased a dust collection system? Everything was working beautifully! At some point, you got the impression that it wasn’t working so well anymore. The at-source air intake isn’t happening correctly anymore. What can you do? Has your system stopped working? Is it serious?

Here are some diagnostic ideas you can undertake on your own. Follow these simple steps to find the source of the problem.

Self-diagnosing the dust collection system

The first thing to look at is the amperage of the fan motor. Amperage is the equivalent of the system's heart. In other words, it’s like taking your pressure at the doctor’s office. Your pressure can be normal, low, or even high. Same thing for your dust collector!

The amperage is normal

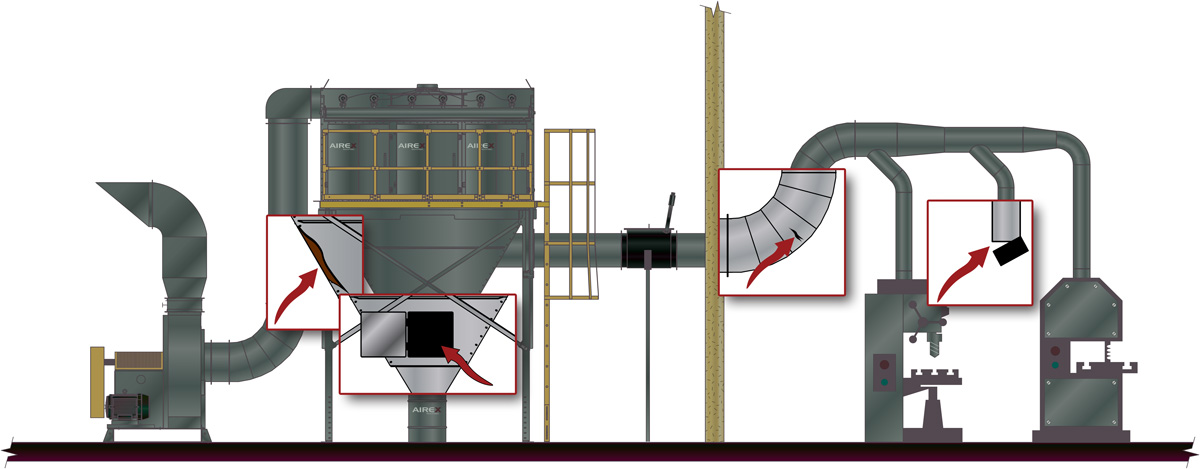

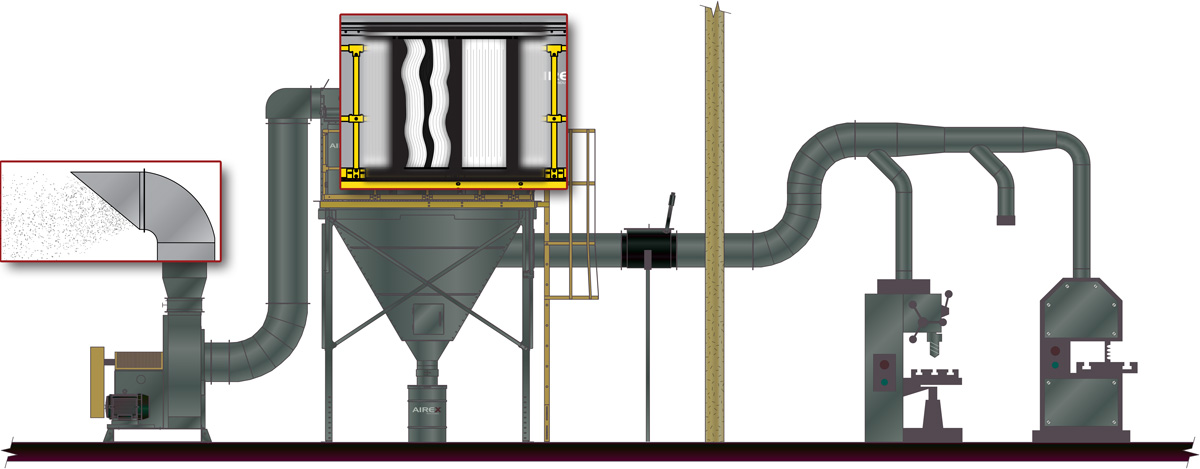

If the amperage is normal, but the intake effectiveness at the work station is insufficient, the air stream is probably coming from elsewhere. So, check for wear such as a leak, crack or hole. In that case, the air takes the easiest route into the dust collector. Therefore, it is no longer drawn in at the right place.

The cause may also be attributed to the addition of a capture line, the removal of a plug on an air inlet, or simply the accidental opening of a damper. A service hatch, such as the one at the bottom of the hopper, may also have stayed open during a routine inspection.

In those situations, the air stream at the capture point is diluted. If you find the source of the problem, like an open door, just close it.

Otherwise, the system will have to be rebalanced. Our experts will naturally be able to help you with that operation.

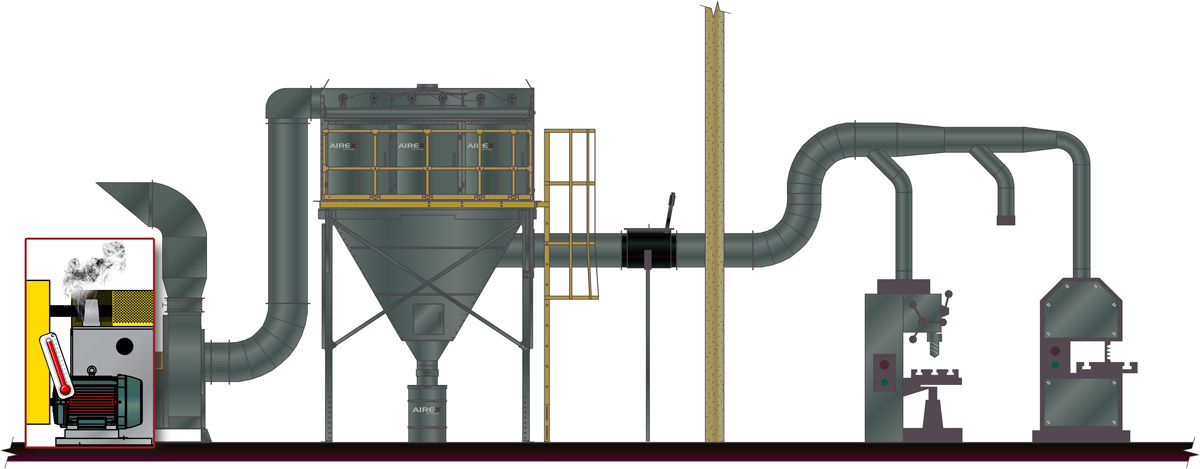

If the amperage is normal, but the air stream is not diluted, the motor may be defective. Bearing friction or even an electrical problem may be the cause. In that case, the motor is pushing more, yet the amperage stays the same because the fan’s performance is affected by the decreased air volume. As a result, the at-source air intake will be reduced.

Check the temperature of the motor. If it’s abnormal, contact an expert to assess the situation.

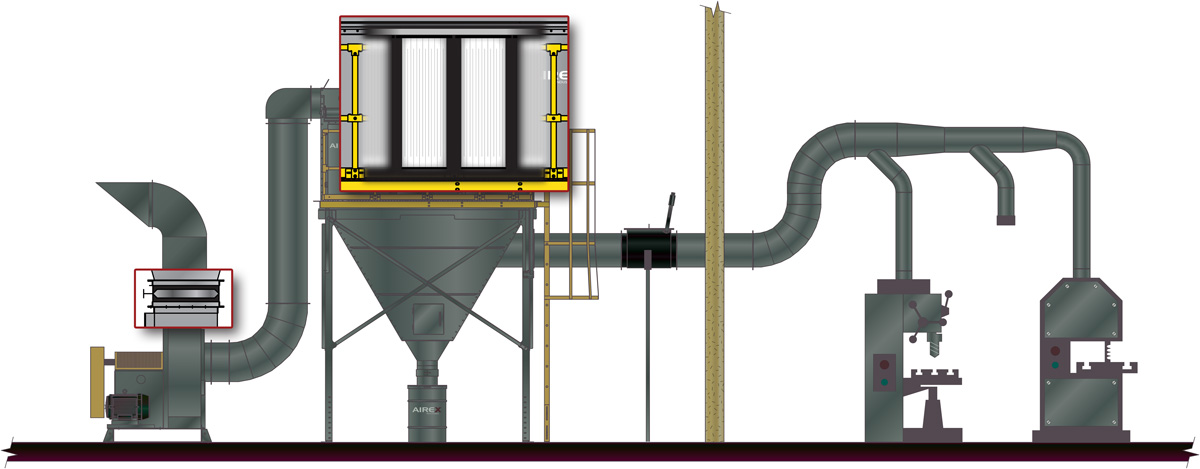

The amperage is high

If the amperage is high, it’s a sign that too much air is passing through the fan. The amperage is directly proportional to the air flow rate through the fan.

Contrary to popular belief, pressure does not increase when a system is blocked. The opposite is true. In this case, the resistance drops. The fan then rotates in a void, like pedalling a bicycle without a chain.

Conversely, an engine that is pushing too hard is getting too much air. It’s like pedalling into the wind. The more wind, the more it pushes. Therefore, your heart rate (the amperage here) increases.

Three things to assess if the amperage is high

- Did you change the filters recently? New filters generate less resistance because they are clean. More air flows into the system, thereby increasing the amperage at the same time. In this case, the amount of air will return to normal when the dust cake builds up on the filters. If needed, temporarily reduce the opening of the flap at the fan exhaust outlet to create a restriction and return to a normal rate.

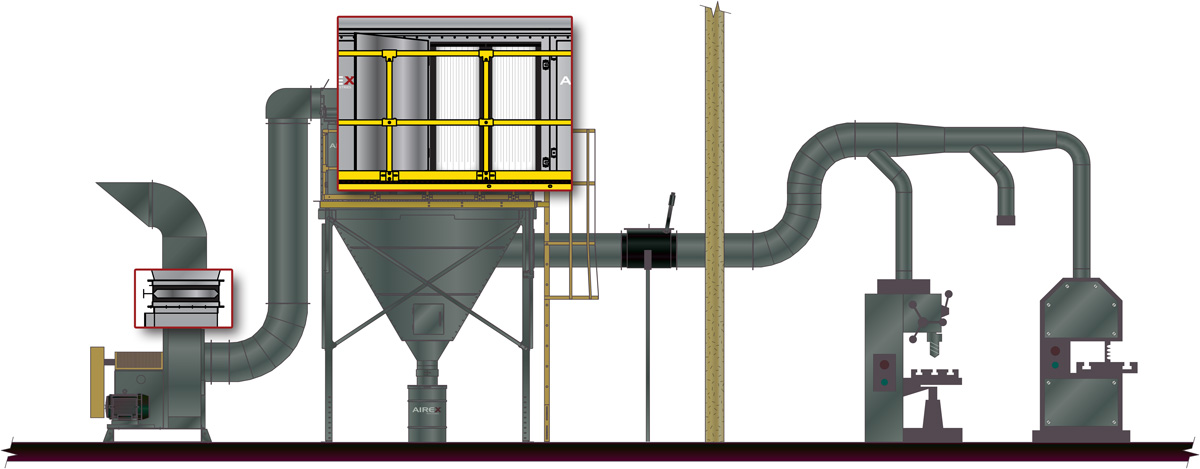

- You haven’t changed your filters? Look for visible dust particles at the dust collector’s exhaust outlet. If yes, it’s because your dust collector is no longer able to filter the air. Filters can have holes or may have burst, or cages may have fallen. This damage lets more air through, which increases the amperage.

In that case, change the damaged filters. However, be sure to use the right strategy because if you change only a few filters and the others are worn out, you could damage the new filters prematurely. Also investigate why the filters are breaking.

- If the filters haven’t been changed recently and there are no dust particle emissions, look elsewhere. Is a hatch or access door to the dust collector open? Has the position of the exhaust outlet flap been changed? Is it open too much? In that case, the resistance on the system decreases, the flow rate increases, and the amperage increases. Return it to the normal position. What needs to be closed must stay closed!

If you haven’t found the source of the problem, it could be electrical in origin or something else. Promptly contact one of our specialists to assess the problem.

We’re here for you!

When a system isn’t working properly, creative solutions can always be found. Rest assured, it’s not always necessary to change everything! At AIREX Industries, we have specialized knowledge in dust collection systems. Our experts are also able to adapt a dust collector’s operation to your reality. Our flexible, resourceful approach can also help you save money!

Remember though, any change to a dust collection system must be made by an expert. Otherwise, you could throw it off balance and reduce its effectiveness.

In our next article, we’ll provide you some examples of issues associated with low amperage. In the meantime, don’t hesitate to contact us!

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?