A Better Understanding of Source Capture Devices

In addition to cleaning the air in your plant, the dust-collection system plays an important role in terms of productivity. Particulate matter released at a work station can affect workers, cause recurring cleaning tasks or compromise the quality of parts under production. To avoid these potentially costly disadvantages, it is important to optimize your central system’s operations by installing the appropriate capture devices upstream.

Several types of equipment may be suitable. Depending on the task and size of the parts being worked on, some solutions will be more suitable than others. Below you will find the advantages and disadvantages of five frequently used capture devices.

The Downdraft Table

Also known as a cartridge downdraft table, this specialized equipment helps eliminate smoke, dust and other pollutants where the worker is working. The way it works is quite simple: the worker places his part on the table and performs the necessary work. The dust is sucked to the bottom of the table and collected by the central filtration system.

Advantages:

- The table becomes the working surface.

- It is compact and affordable.

- The grating can be made from a variety of materials (steel, aluminum, polymer, plastic, wood, etc.) to avoid damaging parts when handled.

Disadvantages:

- You have to work close to the table to benefit from effective suction. Beyond a certain distance, there is a loss of velocity and dust may spread into the work environment.

- Since the table is not mobile, workers must go to it with their parts.

- The size of the parts being machined is limited by the size of the table.

- This piece of equipment is loud.

- The table does not capture all the dust generated by the work.

The Environmental Booth

In terms of efficiency, this is the best of the five solutions. The employee works inside the booth and the dust is sucked towards the bottom. A curtain of air can also be added to prevent dust from spreading and mixing with the air in the plant.

Advantages:

- Highly effective.

- Very flexible, the worker can change positions and move anywhere in the booth.

Disadvantages:

- Noisy, especially since the booth acts like a resonance box.

- Usually requires a lot of floor space.

- The size of the booth limits the size of the parts that can be worked on.

- This is a fixed, heavy piece of equipment that does not move.

- Requires a high air flow from the central system.

Integrated Compact Suction Intake

Source capture requires the integration of high pressure suction equipment (or hood) directly onto the unit. For welding work for example, the nozzle would be equipped with a integrated compact suction intake.

Advantages:

- Does not require additional floor space.

- Great mobility and flexibility. It is an ideal solution when you need to move around a large part or piece of equipment that cannot be moved.

- Does not require workers to change their work methods or equipment.

Disadvantages:

- The high-pressure system is energy intensive.

- Equipment becomes significantly heavier to handle when the hood is added.

- The hood may, in some cases, limit the working angle.

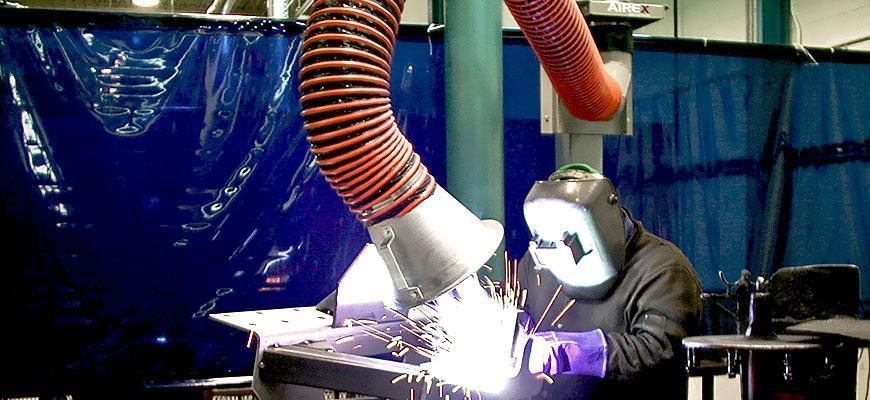

Capture Arm

Connected to the duct network, the worker directs the capture arm toward the source of the fumes. This equipment is therefore hung in the workspace and it needs only to be positioned to perform its suction work.

Advantages:

- Very effective when properly positioned.

- Provides a wide range (up to 20 feet from the starting point) and allows for the adding of an extender.

- Affordable, it has the best effectiveness to price ratio.

- Offers the opportunity to work on any type or size of part.

- Does not require any floor space.

- Very little noise.

Disadvantages:

- Since the work angle is very important in order to have good suction, the worker must make certain to properly position the device.

- The work area is limited by the scope of the device.

Capture Hood

Suspended over a workstation and connected at dust collector through ductwork, the capture hood is favored when a worker generates low density volatile dusts, for example, such as welding fumes.

Advantages:

- Effective when dealing with fine dust

- The capture hood does not take up floor space.

Disadvantages:

- Not very effective with nonvolatile particles.

- Requires a high air flow from the central system.

- The capture hood is usually fixed and not designed to be moved.

As you can see, capture techniques can vary greatly from one another and depend on the needs of the company. Below is a summary table of the solutions presented.

|

AIREX specialists will be able to advise you on the optimal solutions for your plant, based on your needs and various production constraints. Trust our expertise!

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?