Preventing Combustible Metal Dust Explosions - Part 1

In 2015, 838 violations were cited by CNESST for companies failing to comply with health and safety dust control regulations. A large number among non-compliant operations were found with fabricated metal product manufacturers. Recall that processes producing metallic dust fumes exhibit fire and explosion hazards that may in turn jeopardize the safety of workers and company premises.

WHY is metal dust so dangerous ?

Fabricated metal product manufacturing is a contributing factor for the presence of five key elements that, when they occur simultaneously, an explosion takes place from metal dust emissions. Thus the need for workplace vigilance to thwart possible tragedies.

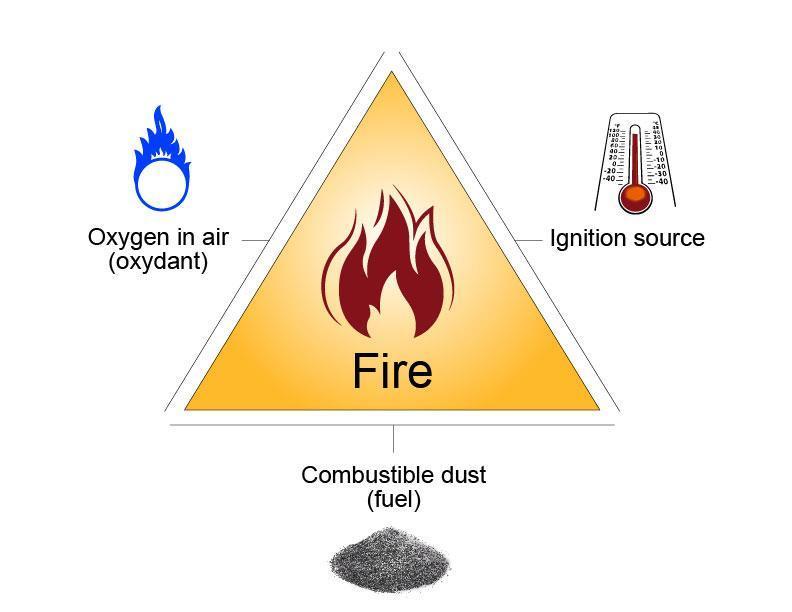

The Fire Triangle

The combination of the first three ingredients leads to spontaneous combustion. This reaction poses a serious hazard that may lead to a fire with ensuing devastation and loss of life.

1st element

Fuel

Several metals combust when exposed to air, especially metal powders.

2nd element

Oxidant

Ingredient that supports and sustains fuel combustion. The mixture of an oxidant (such as oxygen) and fuel in the right proportions may lead to combustion.

3rd element

Ignition Source

Known as the activation energy, the temperature rise associated with the chemical reaction allows the fuel-air mixture to ignite.

Metal Oxidation Reaction

Oxidation is one process among others that may lead to spontaneous combustion. This exothermic reaction occurs when certain metal surfaces are directly exposed to oxygen. Titanium ingots, for example, offer limited reactivity due to the reduced surface areas exposed to ambient air. However, when crushed to a powder, the high surface area of the titanium metal provides ample opportunity for reaction. Indeed, titanium powder is pyrophoric and will spontaneously ignite within 5 minutes.

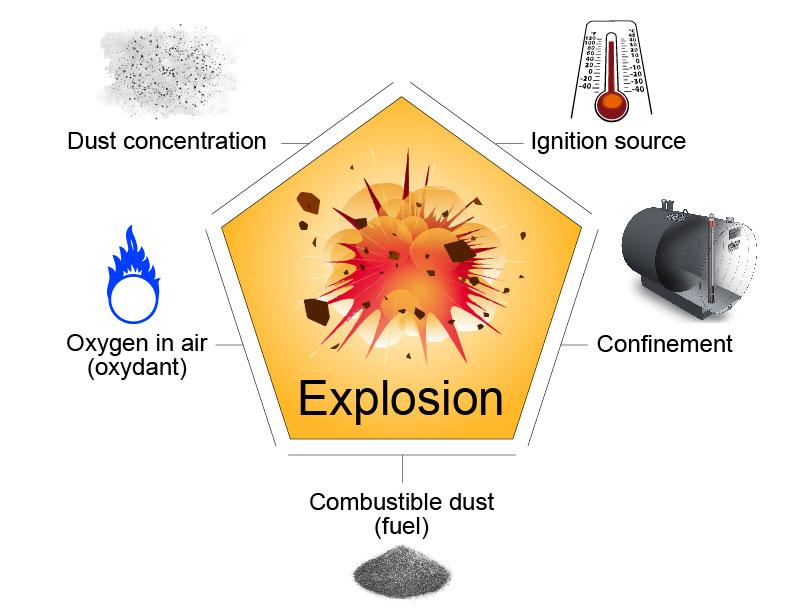

The Explosion Pentagon

As mentioned above, five elements must react at the same time to produce an explosion. Indeed, with two additional ingredients, your fire triangle becomes an explosive mixture.

4th element

Dust Concentration

As we approach minimum concentration levels, suspended particulate matter becomes hazardous. In combination with the first 4 elements, fine metal powders may rapidly oxidize in a flash fire.

5th element

Confinement

Particle dispersion within the confines of enclosed or semi-enclosed spaces is limited. Should dust clouds ignite, rapidly expanding gases within the confined area will deflagrate. Certain metal powders may accelerate reactivity and contribute to explosion violence.

Conclusion

In fabricated metal product manufacturing, an explosion typically occurs when sparks enter the dust collection system. In most cases, you cannot pinpoint the ignition source. In addition, during self-cleaning, filter dedusting produces highly combustible dust clouds that may ignite at any moment. While many situations involve a single explosion, there are often a series of deflagrations. The initial explosion tremor typically shakes dust-laden upper surfaces and the resultant dust clouds in combination with the same or different ignition source(s) trigger secondary explosions. These secondary explosions have historically been the leading cause for personal injury and property damage.

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?