Process Control

Control options are endless, but the cost of implementation index drops as a function of the complexity of the project.

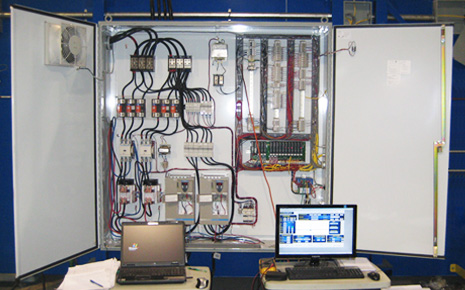

A large part of equipment efficiency concerning industrial ovens, dust collectors or fresh air intake systems is directly linked to the design of control panels.

Team members who specialize in automation and control recommend customized solutions that factor in each equipment, their operating environment and specific needs of the customer. Programming and accessories proposed by our team are designed to provide a perfect balance between system control intelligence and implementation cost.

Implementation Phases

1 - Control Logic

A technical representative must first analyze the parameters and limitations of the system to be built. This is carried out with the customer’s cooperation and allows us to determine operational needs and strategies such as equipment operating times and adapting system control units to equipment and/or processes. A comprehensive analysis will allow us to give you unparalleled circuit logic that can reap benefits in energy consumption for your manufacturing facility.

2 - Control Sequence

The representative submits his analysis to the automation technician, whose task is to convert control logic into machine code language. This includes writing the program, manufacturing and setting up the panel accessories. A series of shop tests is performed to ensure that request handling is properly managed.

Territory served

WE SERVE THE GREATER MONTREAL AREA, INCLUDING THE NORTH AND SOUTH SHORES.

![]()

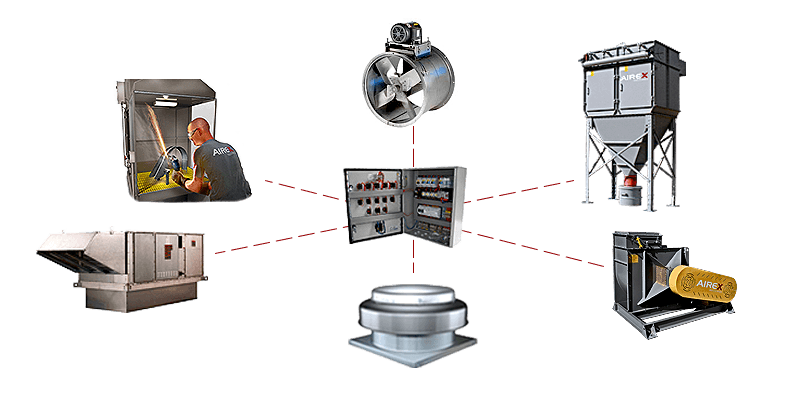

Control Centralization

Manufacturing plants with decentralized heating, ventilation and air-conditioning equipment (HVAC) frequently manage each system independently of the others.

Airex has become an expert in centralizing HVAC equipment control by working with industries dealing with this type of situation.

Certifications:

- CSA

- Electrical Safety Authority of Ontario

- Member of the Corporation des maîtres électriciens du Québec (CMEQ)

Advantages of Centralizing HVAC Equipment:

- Generates energy consumption savings

- Reduces negative pressure in the building

- Improved temperature control

- Maintenance effectiveness

- Manages equipment via telemetry

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?