Cartridge Dust Collector

Platinum Series

Discover The Power Of The New Generation Of Vertical Cartridge Dust Collectors

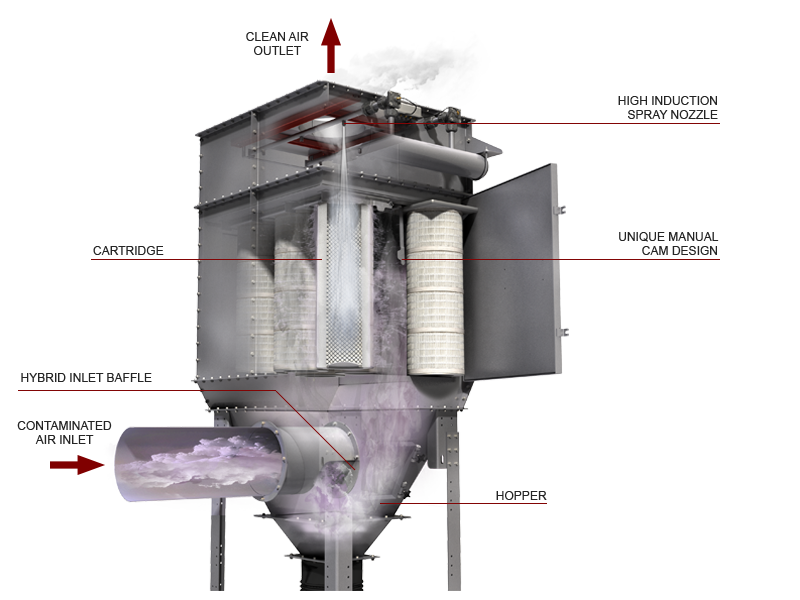

Airex Industries PlatinumTM Series Dust Collectors are different from other dust collectors. Their ability to filter highly-contaminated air volumes in an extremely compact format is what sets them apart from the rest. As part of an efficient compressed air self-cleaning system, the cartridges allow for the continuous filtration of sub-micron dust particles with a constant differential pressure loss.

Our PlatinumTM dust collectors have doors and a manual cam system that require no tools and allows for an easy cartridge change out.

Main Advantages At A Glance

High Filtration Capacity

Models from 2 to 224 cartridges and up to 100 000 CFM capacity.

Custom Engineering

Special needs and custom designs available with PlatinumTM systems.

Low Inital Cost

The optimization of our design and assembly technics allows us to offer highly competitive prices.

Vertical Cartridge Design

Unlike horizontal cartridge designs that reduce filtering surface efficiency by up to 30%, Airex Industries PlatinumTM series dust collectors maintain a 100% filtration rate at all times.

Vertical Filtration Principle

How The Cartridge Dust Collector Works

The dust-laden gases enter through the side intake of the dust collector’s hopper, under vacuum or pressure (except for bin vents, where the air comes in from the bottom).

The gases are then filtered through the cartridges and exit through the openings into the clean air plenum. The clean air can either be channeled outside or re-circulated depending on the application.

Advantages

Fast, Simple and Safe Cartridge Replacement

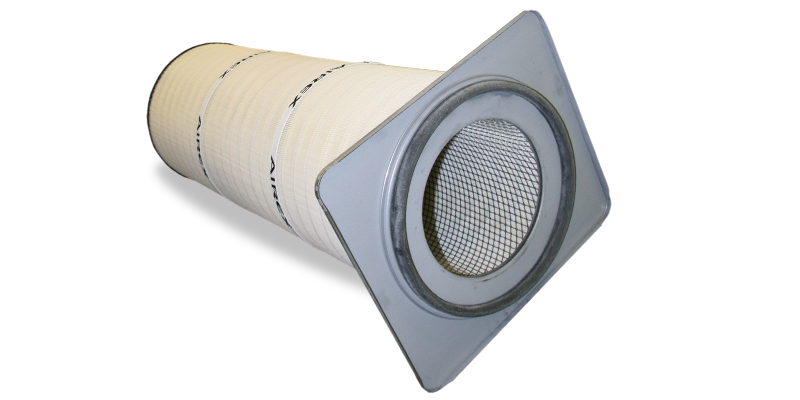

Cartridge replacement is performed outside the dust collector and requires no tools. This eliminates the need to work within a confined space and allows the worker to access the cartridge without getting dirty. The cartridge comes with a rectangular top plate that simplifies manipulation and eliminates potential installation errors.

Continuous Operation

Unlike other types of dust collectors such as the shaker, the cartridge dust collector does not have to be stopped in order to remove and clean dust particles from its filters.

Economical

The cartridge dust collector is an economical choice because it requires minimal maintenance: only periodic cartridge replacement is necessary (depending on the application).

Territory served

WE SERVE THE GREATER MONTREAL AREA, INCLUDING THE NORTH AND SOUTH SHORES.

![]()

Filtration Technology

We Have the Right Filtering Media for Your Needs

In terms of performance, one of the most important criteria during the initial design of a dust collection system is the proper selection of the filtering media.

There are several cartridge models providing adaptation flexibility based on the characteristics of the various types of aerosols. The filtration effectiveness of Airex cartridges can achieve a level equivalent to HEPA, classified as MERV 16. In fact, a single cartridge has a total filtering surface that can reach up to 315 sq. ft. The compact aspect of such a filtering medium makes it a highly prized solution when the available space is limited.

Common Features

End Cap and Gaskets

Our standard end caps are made of galvanized metal (16" x 14.25") while our D-Shape gaskets are fabricated with continuous rubber (0.5" W x 0.625" H).

Operation Temperature

Cartridges maximum continuous operating temperature is 250 °F (120 °C) while the maximum short term operating temperature can reach up to 295 °F (145 °C).

Weight and Dimensions

Weight : 22 lb

Height : 36"

Outside diameter : 12.75"

Inside diameter : 8.3"

| 85% Cellulose/ 15% Polyester |

8 oz Spun Bond Polyester |

Cell / Poly with Nanofiber |

8 oz Spun Bond PTFE |

|

| Filtration Area | 315 ft2 | 130 ft2 | 315 ft2 | 130 ft2 |

| Efficiency | 99.7% @ 0.5 microns | 97% @ 0.5 microns | 99% @ 0.37 microns | 99.4% @ 0.08 microns |

| MERV | 9 @ 840 cfm | 10 @ 500 cfm | 15 @ 840 cfm | 16 @ 500 cfm |

| Permeability | 17 cfm / ft2 @ 0.5" H2O | 20 cfm / ft2 @ 0.5" H2O | 25 cfm / ft2 @ 0.5" H2O | 5-8 cfm / ft2 @ 0.5" H2O |

| Pleat Count | 315 | 130 | 315 | 130 |

| Pleat Depth | 2" | 2" | 2" | 2" |

| Resistance | ||||

| Acid | ** | *** | ** | *** |

| Alkaline | * | * | * | * |

| Abrasion | *** | **** | *** | **** |

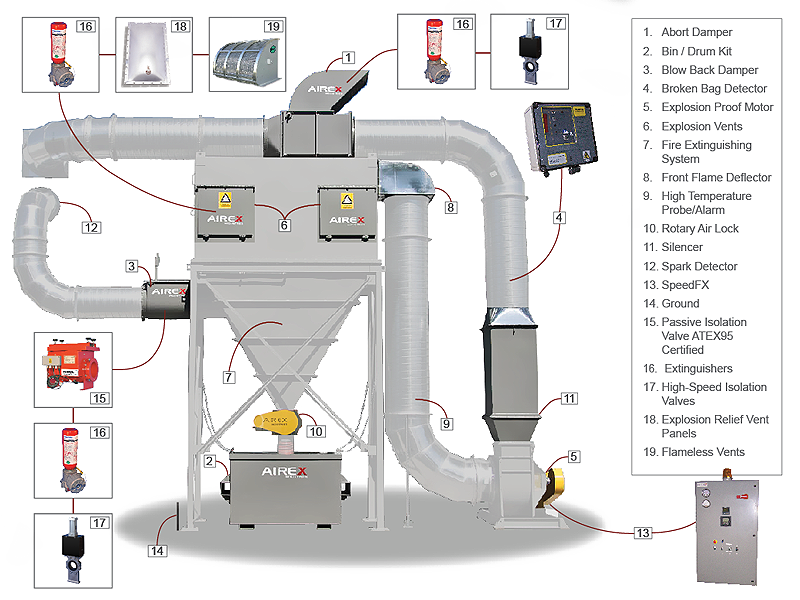

Accessories

Enhance Your Performance and Security

Some options like the SpeedFXTM can vary motor speed and energy consumption thus improving efficiency.

A number of Airex accessories aim to meet NFPA regulations, preventing against fire and explosions while better protecting workers and facilities.

Fire Protection Accessories

Abort Damper

Connected with a proper spark or fire detection system, the abort damper redirects exhaust air into the atmosphere as soon as a spark is detected.

Blow Back Damper

Ensure there is a seal, if a fire or explosion occurs in the dust collector, preventing return of smoke and fire to the shop by the intake ductwork.

Explosion Vents

The explosion vents redirect a propagating flame or explosion to atmosphere via pressure rated washers.

Rotary Air Lock

Designed to control the flow of discharge material from a dust collector or other type of process while maintaining an air seal.

Spark Detection & Fire Extinguishing System

Counters the spread of fire with a temperature probe and sprinkler. : Spraying the collector and stops the blower (eliminating oxygen intake).

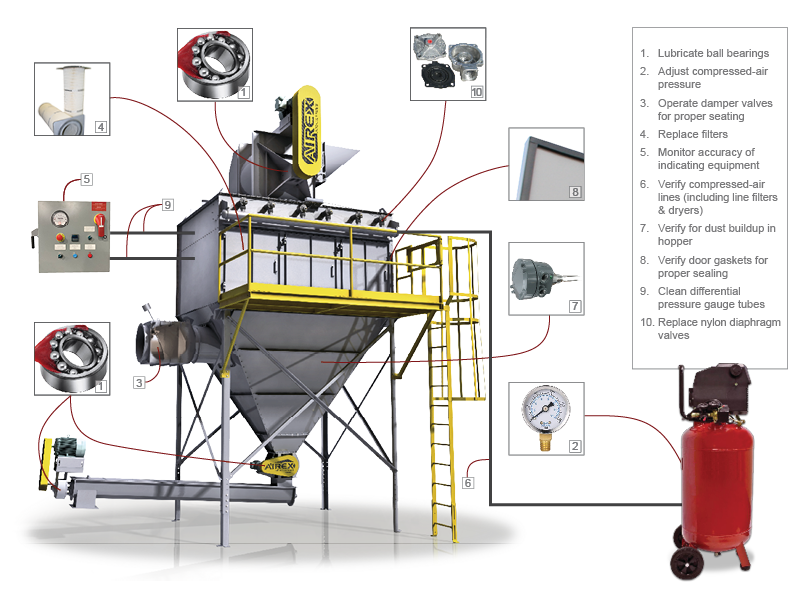

Preventive Maintenance

Use a Proactive Approach to Increase the Lifespan of Your Unit

Like other industrial equipment, a dust collector has an assortment of components that you need to keep an eye on to ensure the unit is operating optimally. If these components are not maintained, the company could find itself in a potentially risky situation in terms of health and safety.

Airex offers a preventive maintenance contract that can increase the useful life of your dust collection system and its accessories. This type of program is also an excellent strategy for avoiding the unforeseeable in terms of breakages and unit stoppages.

By investing in the maintenance of your dust collector, you will also save money by avoiding emergency repair costs that are of course much most onerous over the medium and long term.

Stay Alert for Early Signs of Deterioration

Visual Inspection

Be vigilant to the appearance of corrosion, dust accumulation or even wear and tear of your system.

Variation of Noise and Vibration

Listen for a compressed air leak, fan vibration, or even an unusual sound from your system.

Tracking Operation Parameters

Make sure the performance indicators stay within the prescribed limits of your system.

OPTIMIZE YOUR INDUSTRIAL DUST COLLECTOR PERFORMANCE

REQUEST AN EXPERT'S OPINION

![]()

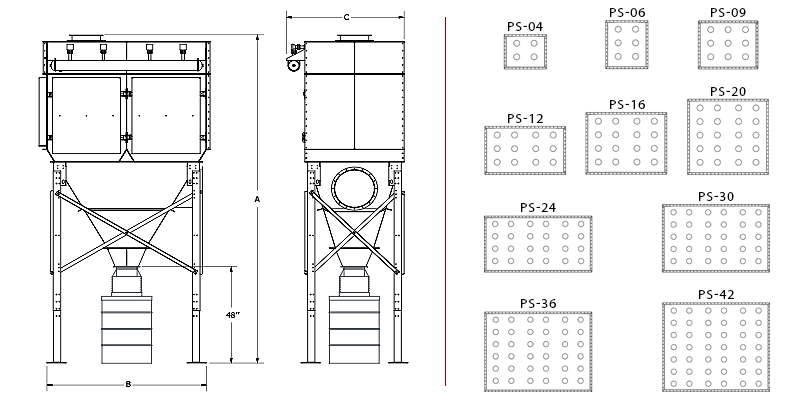

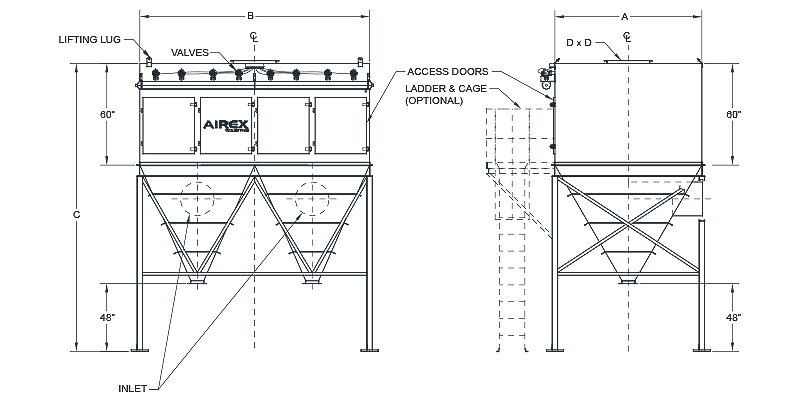

Specifications - PS

|

Model / |

Valves Qty |

Dimensions | Filtration Area |

Weight (lbs/kg) |

|||||||||

| A |

B |

C |

Cellulose / Nanofiber |

Spun Bond |

|||||||||

| in | mm | in | mm | in | mm | ft2 | m2 | ft2 | m2 | lb | kg | ||

| PS-04 | 2 | 133” | 3379 | 91” | 2311 | 47” | 1193 | 1260 | 117 | 520 | 48 | 1800 | 810 |

| PS-06 | 2 | 133” | 3379 | 106” | 2692 | 45” | 1143 | 1890 | 176 | 780 | 73 | 1999 | 900 |

| PS-09 | 3 | 147” | 3733 | 118” | 2997 | 65” | 2794 | 2835 | 264 | 1170 | 109 | 2274 | 1023 |

| PS-12 | 4 | 177” | 4419 | 105” | 2667 | 87” | 2895 | 3780 | 352 | 1560 | 145 | 3301 | 1485 |

| PS-16 | 4 | 175” | 4368 | 119” | 3022 | 87” | 2895 | 5040 | 469 | 2080 | 193 | 3706 | 1668 |

| PS-20 | 4 | 187” | 4724 | 133” | 3378 | 87” | 2895 | 6300 | 586 | 2600 | 242 | 3988 | 1795 |

| PS-24 | 6 | 195” | 4953 | 120” | 3048 | 115” | 2921 | 7560 | 703 | 3120 | 290 | 5137 | 2312 |

| PS-30 | 6 | 187” | 4749 | 134” | 3404 | 128” | 3251 | 9450 | 879; | 3900 | 363 | 5618 | 2528 |

| PS-36 | 6 | 213” | 5410 | 148” | 3759 | 128” | 3251 | 11340 | 1055 | 4680 | 435 | 5991 | 2696 |

| PS-42 | 6 | 255” | 6477 | 162” | 4114 | 128” | 3251 | 13230 | 1230 | 5460 | 508 | 7084 | 3188 |

Specifications - DCCH

|

Model / |

Valves Qty |

Dimensions | Filtration Area |

Weight (lbs/kg) |

|||||||||

| A |

B |

C |

Cellulose / Nanofiber |

Spun Bond |

|||||||||

| in | mm | in | mm | in | mm | ft2 | m2 | ft2 | m2 | lb | kg | ||

| 48 | 8 | 89” | 2261 | 162” | 4115 | 257” | 6528 | 15120 | 1392 | 6240 | 583 | 6930 | 3150 |

| 48D | 8 | 89” | 2261 | 162” | 4115 | 194” | 1928 | 15120 | 1392 | 6240 | 583 | 6300 | 2864 |

| 50D | 10 | 75” | 1905 | 202” | 5131 | 204” | 5182 | 15750 | 1450 | 6500 | 607 | 6732 | 3060 |

| 56D | 8 | 103” | 2616 | 162” | 4115 | 207” | 5258 | 17640 | 1624 | 7280 | 1680 | 7233 | 3288 |

| 60D | 10 | 89” | 2261 | 202” | 5131 | 205” | 5207 | 18900 | 1740; | 7800 | 729 | 7307 | 3321 |

| 64D | 8 | 118” | 2616 | 162” | 4115 | 219” | 5563 | 20160 | 1856 | 8320 | 778 | 8100 | 3682 |

| 70D | 10 | 103” | 2616 | 202” | 5131 | 215” | 5461 | 22050 | 2030 | 9100 | 850 | 8212 | 3733 |

| 80D | 10 | 118” | 2997 | 202” | 5131 | 217” | 5512 | 25200 | 2320 | 10400 | 972 | 9193 | 4179 |

| 84D | 12 | 103” | 2616 | 243” | 6172 | 222” | 5639 | 26460 | 2436 | 10920 | 1021 | 9339 | 4245 |

| 96D | 12 | 118” | 2997 | 243” | 6172 | 222” | 5639 | 30240 | 2784 | 12480 | 1166 | 10442 | 4746 |

| 112T | 14 | 118” | 2997 | 283” | 7188 | 222” | 5639 | 35280 | 3248 | 14560 | 1361 | 12513 | 5688 |

| 128T | 16 | 118” | 2997 | 324” | 8230 | 222” | 5639 | 40320 | 3712 | 16640 | 1555 | 14587 | 6630 |

| 144T | 18 | 118” | 2997 | 364” | 9245 | 222” | 5639 | 45360 | 4176 | 18720 | 1750 | 16425 | 7466 |

| 160T | 20 | 118” | 2997 | 405” | 10287 | 234” | 5944 | 50400 | 4640 | 20800 | 1944 | 17584 | 7993 |

| 176T | 22 | 118” | 2997 | 446” | 11328 | 245” | 6223 | 55440 | 5104 | 22880 | 2138 | 18725 | 8511 |

| 192T | 24 | 118” | 2997 | 486” | 12344 | 257” | 6528 | 60480 | 5568 | 24960 | 2333 | 19864 | 9029 |

| 208T | 26 | 118” | 2997 | 526” | 13360 | 269” | 6831 | 65520 | 6032 | 27040 | 2527 | 21785 | 9902 |

| 224T | 28 | 118” | 2997 | 567” | 14402 | 281” | 7138 | 70560 | 6496 | 29120 | 2722 | 23680 | 10764 |

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?