How to protect workers’ breathing zone?

By reading our previous article, you will understand that particles floating in the air can be very harmful to people’s health. However, there are solutions for protecting workers’ breathing zone when airborne contaminants are present in your environment. Here are our recommendations.

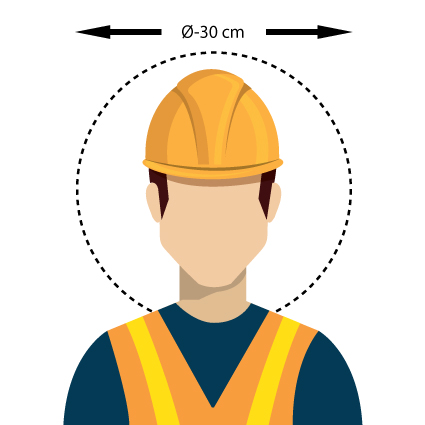

What is the breathing zone?

The breathing zone is an imaginary bubble around a worker’s head. It measures about 30 cm in diameter, and its centre is at ear level.

How can exposure to dust be controlled?

If your processes generate harmful dust, it is your responsibility to make arrangements for limiting its presence in the workers’ breathing zone.

Breathing zone imaginary bubble

Masks: the last option

In accordance with the occupational health and safety standards, the employer must consider all means for managing workers’ exposure to contaminants before using personal protective breathing equipment. Even so, in some applications, like abrasive blasting, it’s the only way to ensure 100% protection of your team’s health.

Organizational measures to consider

- Improving the ventilation by increasing the number of air changes and the fresh-air intake in order to reduce the dust concentration.

- Performing administrative controls. By establishing an authorized maximum daily duration for an activity or by prohibiting access to certain facilities when they’re in operation.

- Modifying the process or work materials, such as replacing silica with a harmless substance for cleaning with abrasive blasting.

- Substituting solvents.

Housekeeping

Cleaning the premises and the equipment is basic protection. Using an industrial vacuum with an explosion-proof motor or using an air shower is always preferable to a broom and a compressed-air blow gun (which is prohibited anyway!) in order to avoid creating clouds of dust.

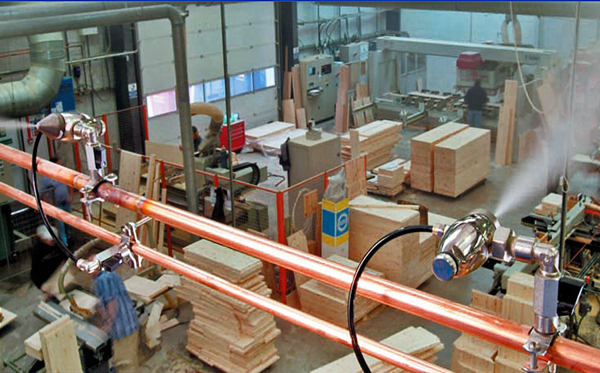

Wet processes

There are various ways of limiting the spread of dust by introducing water into your processes. It agglomerates with suspended particles, which then drop to the ground, thereby protecting the breathing zone. Here are two possible approaches:

- At the source with, for example, a water jet cutting machine.

- In the environment with, especially the wood and mining industries, atomizers or humidifiers that keep the air moist in the work environment.

Confinement

When a process produces harmful dust, you can confine it in order to prevent it from spreading. An at-source dust capture system (with a covering or a hood) circumscribe the dust to its emission area.

Process upgrade to improve emission points confinement.

Extracting contaminants with a collection system

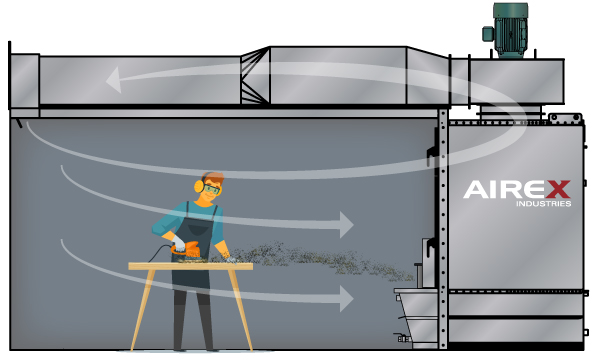

A dust collection system can reduce exposure to contaminants in workers’ breathing zone, either with laminar flow or at-source capture. Choosing the most appropriate method depends on a number of factors, including the type and size of the particles present and the nature of your process.

Dust removal through at-source capture: this method minimizes the circulation of particles in the environment, and therefore in the breathing zone. For it to be effective, the collection must be done as close as possible to the emission source and at a sufficient speed to prevent dispersal. The worker must also avoid blocking the airflow and should not have equipment there that creates other airstream nearby (like a personal fan). The system can consist of a hood placed near the workspace, an extraction device attached right to the tool, or even a downdraft table. Therefore, some solutions can be mobile or fixed.

Laminar flow: units like the environmental booth create a horizontal airflow for directing dust generated at its emission point towards the extraction port located at the bottom of the chamber. This way, it’s possible to limit the presence of contaminants in the breathing zone because the particles are pushed sideways.

Obviously, this approach is effective only if the worker’s position doesn’t interfere with the airflow. In fact, a back-to-the-flow position can create turbulence and disrupt the effectiveness of laminar flow.

Last resort; ambient air filtration

If it turns out that the particles can’t be captured before they reach the worker’s breathing zone, their concentration must then be minimized. The Power Wall unit is perfectly suited for this type of situation. This type of machine can be incorporated into the environment without disrupting work habits. However, this option can be considered only if the exposure value is met.

Will you have to start from scratch to resolve the problem?

In most cases, no! We try to avoid unnecessarily replacing your equipment. Whatever your challenges are, our experts can help you find a solution tailored to your environment and take action on an existing device or process. Together, we'll identify the hazards and introduce the adjustments needed for optimizing the capture of harmful particles. Don’t hesitate to rely on us!

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?