Shaker Dust Collector

Econoshake Series

You Get Your Money’s Worth With The Shaker-Type Dust Collector

The Econoshake dust collector series boast high efficiency filtration and can handle high air volumes with moderate dust loads.

Their technology requires equipment shutdown for periodic cleaning. Their intermittent usage make them ideal candidates for schools and small to medium-sized businesses.

Different configurations of the shaker-type dust collector are available, such as the square-box (SCS(T)) unit and the second unit equipped with a pre-filter cyclonic effect (CE) for heavier dust loads.

Main Advantages At A Glance

Low Initial Cost

The simple design of the shaker dust collector means lower capital investment compared to compressed air self-cleaning units.

Compact

Ideal for reduced spaces, the simple design facilitates implementation despite space constraints.

Low Energy Consumption

Designed to operate intermittently and without compressed air under moderate dust load conditions, you can expect lower energy bills.

Low Maintenance

No valves, no diaphragm replacement. The use of commonly available standard filter media does not limit the user to a sole source / single supplier.

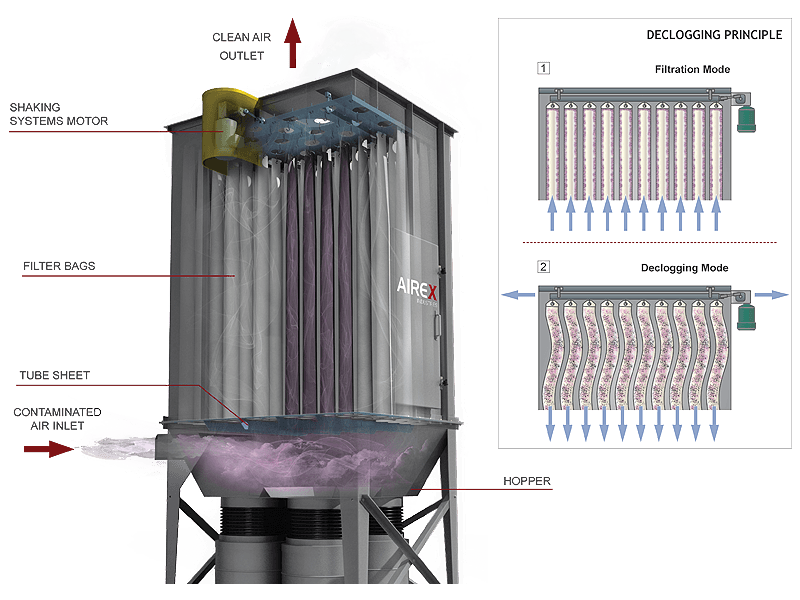

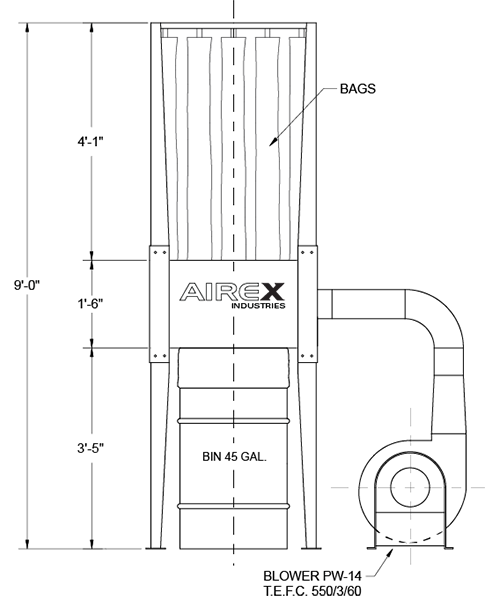

Vertical Filtration Principle

How The Shaker Dust Collector Works

Dust particulate is captured within the shaker dust collector; as particle velocity decreases, the heavier fractions fall directly to the hopper while the fines are drawn against the inside surfaces of the bags. The filtered air expelled from the shaker dust collector may be recirculated within the building or released outside.

To clean bags, simply activate the integrated electric shaker system. Shaker frequency varies according to the quantity and type of accumulated dust particulate. During the cleaning cycle, you are required to shut down the blower to allow particles to fall and settle down in the hopper.

Technological Features

Polyester Filter Bags

Filter fabric is specially treated to facilitate dust cake release during shakedown. Filter cloths are also temperature resistant up to 275°F.

Programmable Shaker Frequency

PLC-controlled systems provide automated filter cleaning schedules.

Quiet Operation

With no diaphragm valves required to clean obstructed filter media, shaker-type dust collectors operate more quietly when in use.

PARTICIPATE IN A LUNCH AND LEARN OFFERED BY AIREX INDUSTRIES

SUBSCRIBE NOW

![]()

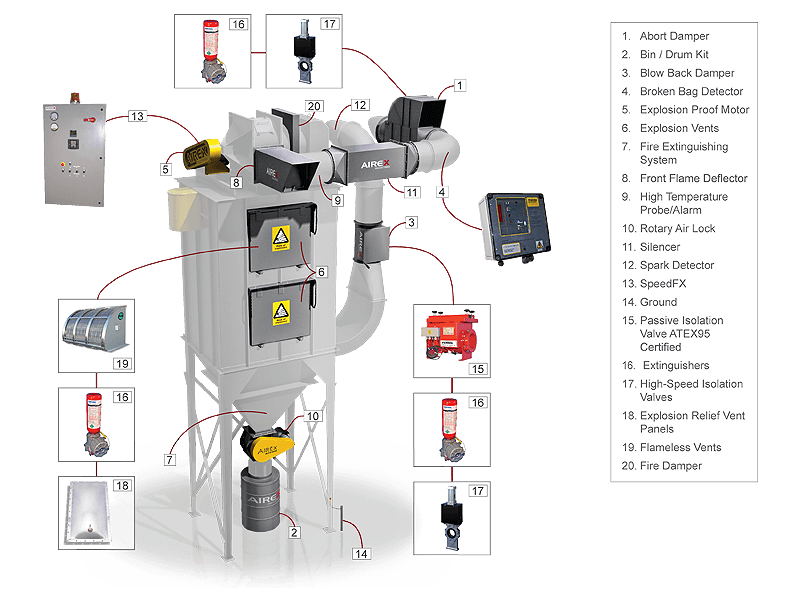

Accessories

Enhance Your Performance and Security

Some options like the SpeedFXTM can vary motor speed and energy consumption thus improving efficiency.

A number of Airex accessories aim to meet NFPA regulations, preventing against fire and explosions while better protecting workers and facilities.

Fire Protection Accessories

Abort Damper

Connected with a proper spark or fire detection system, the abort damper redirects exhaust air into the atmosphere as soon as a spark is detected.

Blow Back Damper

Ensures there is a seal, if a fire or explosion occurs in the dust collector, preventing return of smoke and fire to the shop by the intake ductwork.

Explosion Vents

The explosion vents redirect a propagating flame or explosion to atmosphere via pressure rated washers.

Rotary Air Lock

Designed to control the flow of discharge material from a dust collector or other type of process while maintaining an air seal.

Spark Detection & Fire Extinguishing System

Counters the spread of fire with a temperature probe and sprinkler. : Spraying the collector and stops the blower (eliminating oxygen intake).

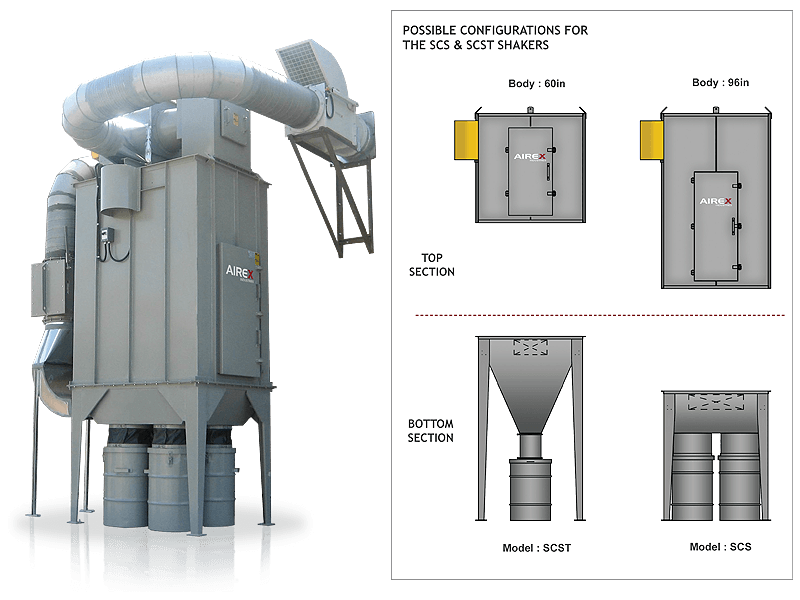

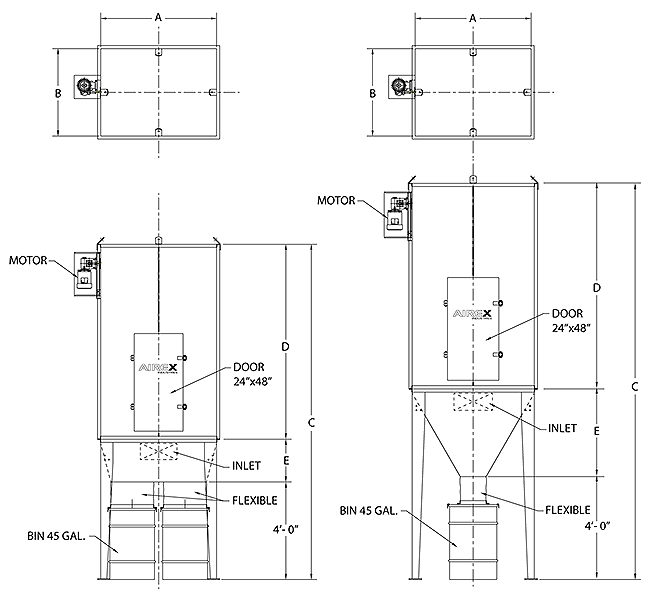

SCS - SCST Model

A Small Unit That Can Handle Big Jobs

Recognized for its robust quality manufacturing, the SCS(T) is definitely the least expensive product line among all categories of industrial-rated units. Its compact design is well suited for inside and outside locations with space restrictions.

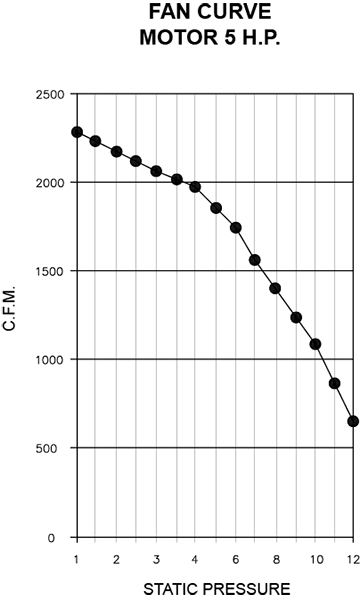

The SCS(T) may be equipped with a direct or indirect drive whose motor output varies as a function of system static pressure and flow rates within network conduits. In addition, this unit offers filtration surfaces from 100 to 1031 sq. ft.

When exposed to potentially explosive dust, rigid collars are required at hopper & barrel interfaces as a means to ensure air-tight connections within dust collector housings.

Possible Configurations

Body Height

Filter bags come in two sizes, either 60 or 96 inch lengths.

SCS Collector

The SCS comes equipped with a lower hopper that may be connected to a maximum of 4 barrels, thereby extending scheduled maintenance frequencies.

SCST Collector

The SCST only requires a single barrel, giving us the opportunity to install a rotary valve. Additional vertical clearance will be needed, nonetheless, to accommodate the higher hopper.

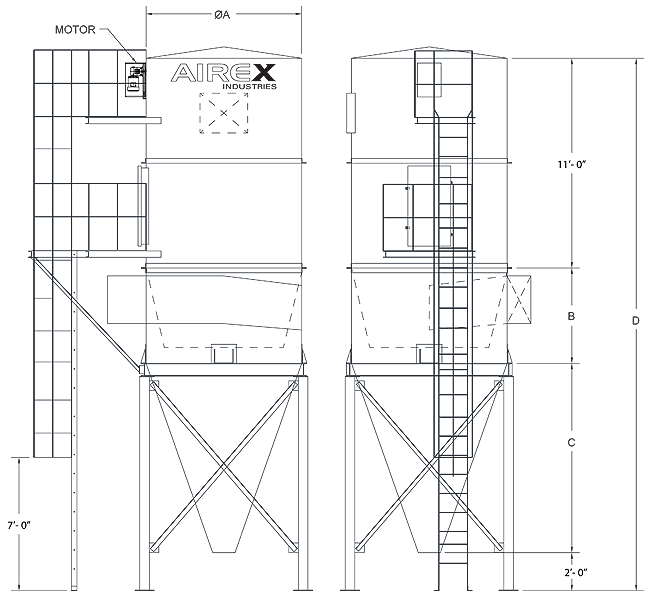

CE Model

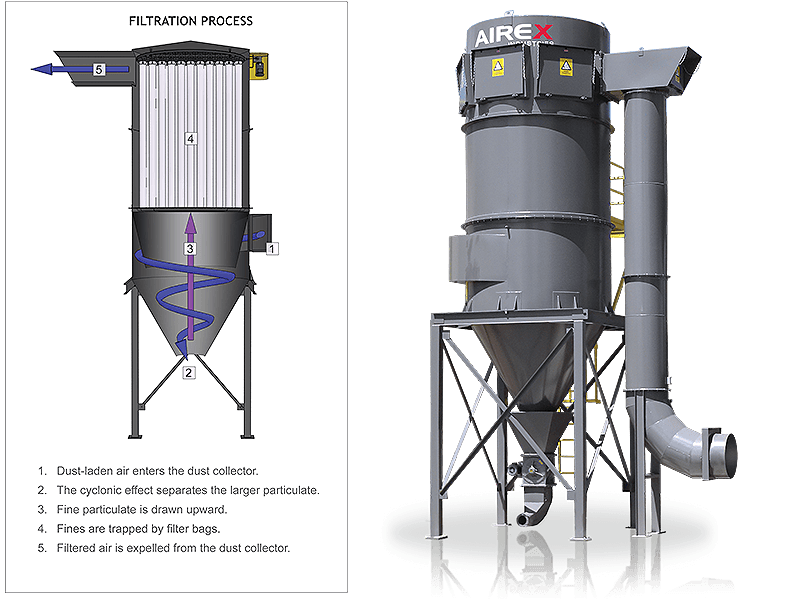

Shaker Dust Collector With Cyclonic Separation Principle For Particulate Matter

The benefits of cyclonic effect technology are well known among customers with large-scale requirements. In response to this need, the CE shaker-type dust collector offers remarkable capacity with high volume filtration. Filtration surfaces range from 1584 to 14007 sq. ft.

Particulate matter at the bottom of the hopper is typically conveyed pneumatically or screw-fed to a container, whose large storage capacity minimizes maintenance.

Operation

Collected dust particulate passes through initial filtration, whose centrifugal force separates the heavier fractions that migrate along the walls to the base of the hopper.

The lighter dust is drawn upwards for subsequent (secondary) filtration. At this step of the process, fine particulate is trapped within the cloth mesh of filter bags.

The filtered air meanders on to the shaker dust collector exit to be recirculated within the building or exhausted outside.

IMPROVE AIR HANDLING OF YOUR FACILITIES

I WANT TO KNOW MORE

![]()

Specifications

CE Model

Lower end line of shaker dust collector, It also happens to be the only open type unit in the line up, meaning that the filters are not enclosed as with the other models.

It is ideal for those who are on a very tight budget and cannot afford the more efficient and much more convenient higher end models of shaker dust collector.

SCS & SCST Model

| Model | CFM Max ft3/min |

A | B | C | D | Inlet | Weight (lb) |

Filtration Area ft2 |

| CE-121 | 14,200 | 7'-6" | 3'-9" | 6'-9" | 23'-6" | 13"x 33" | 6,951 | 1,584 |

| CE-151 | 17,700 | 8'-6" | 5'-3" | 7'-7" | 25'-10" | 15"x 39" | 8,338 | 1,977 |

| CE-163 | 19,200 | 9'-0" | 5'-4" | 8'-0" | 26'-4" | 16"x 40" | 9,396 | 2,134 |

| CE-199 | 23,400 | 9'-6" | 5'-7" | 8'-6" | 27'-1" | 17"x 43" | 10,111 | 2,605 |

| CE-223 | 26,200 | 10'-0" | 5'-9" | 8'-11" | 27'-8" | 18"x 45" | 10,829 | 2,920 |

| CE-253 | 29,800 | 10'-6" | 6'-0" | 9'-4" | 28'-4" | 19"x 48" | 11,560 | 3,312 |

| CE-265 | 31,200 | 11'-0" | 6'-2" | 9'-9" | 28'-1" | 20"x 50" | 12,379 | 3,469 |

| CE-301 | 35,400 | 11'-6" | 6'-4" | 10'-2" | 29'-6" | 21"x 52" | 13,160 | 3,941 |

| CE-337 | 39,700 | 12'-0" | 6'-5" | 10'-8" | 30'-1" | 21"x 53" | 14,704 | 4,412 |

| CE-397 | 46,700 | 13'-0" | 6'-8" | 11'-6" | 31'-2" | 23"x 58" | 16,333 | 5,197 |

| CE-464 | 54,600 | 14'-0" | 7'-4" | 12'-4" | 32'-8" | 25"x 64" | 18,211 | 6,074 |

| CE-535 | 63,000 | 15'-0" | 7'-8" | 14'-0" | 34'-8" | 27"x 68" | 22,616 | 7,004 |

| CE-607 | 71,500 | 16'-0" | 8'-2" | 14'-11" | 36'-1" | 29"x 74" | 25,106 | 7,946 |

| CE-685 | 80,700 | 17'-0" | 8'-7" | 15'-9" | 37'-4" | 32"x 79" | 27,375 | 8,967 |

| CE-793 | 93,400 | 18'-0" | 9'-0" | 16'-8" | 38'-8" | 33"x 84" | 30,284 | 10,381 |

| CE-871 | 102,600 | 19'-0" | 9'-4" | 17'-6" | 39'-10" | 35"x 88" | 32,604 | 11,402 |

| CE-979 | 115,300 | 20'-0" | 9'-9" | 18'-4" | 40'-1" | 37"x 93" | 35,139 | 12,816 |

| CE-1070 | 126,000 | 21'-0" | 10'-2" | 19'-3" | 41'-5" | 39"x 98" | 37,759 | 14,007 |

Modular Model

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?