Preventing Combustible Metal Dust Explosions - Part 4

If your business specializes in fabricated metal production, your installation is most probably equipped with a dust collection system. The design of such systems requires expertise and few manufacturers possess the necessary inside knowledge in air decontamination. For this reason, this last post will address the required minimum specifications for a dust collection system handling highly explosive metallic particulate matter.

HOW may we minimize risk and still be code compliant?

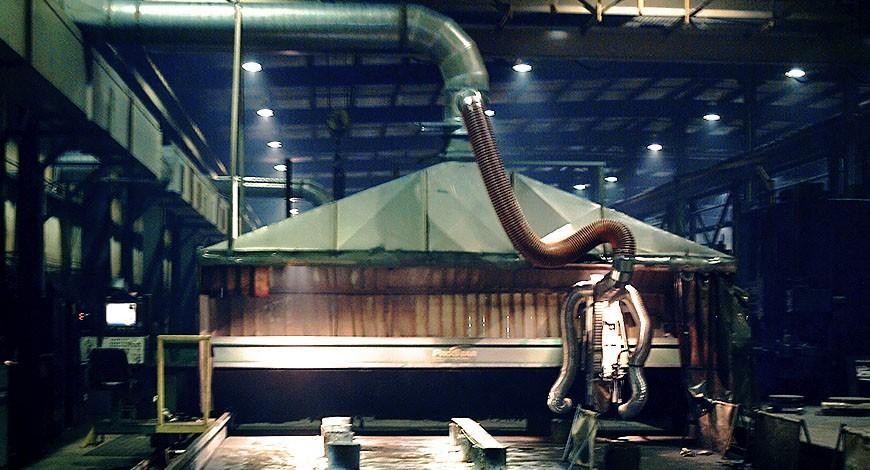

As explained in previous posts, fine particulate emissions from metallic component machining pose a serious fire hazard that may lead to deflagration. The different regulatory bodies (such as CNESST and NFPA) offer similar advice when handling highly explosive metallic powder and for obvious safety reasons suggest using wet dust collector systems, such as the Wetrex, instead of the classic approach employing baghouse or cartridge collectors. Under exceptional circumstances, dry systems may be used to filter combustible metal dust provided they are installed in an outside location with a minimum 15 meter clearance from plant buildings and are furnished with necessary explosion relief (venting, suppression, isolation). It comes as no surprise that the Wetrex offers inherent safety features and cost-saving advantages when the time comes to choose highly explosive metallic dust filter technology.

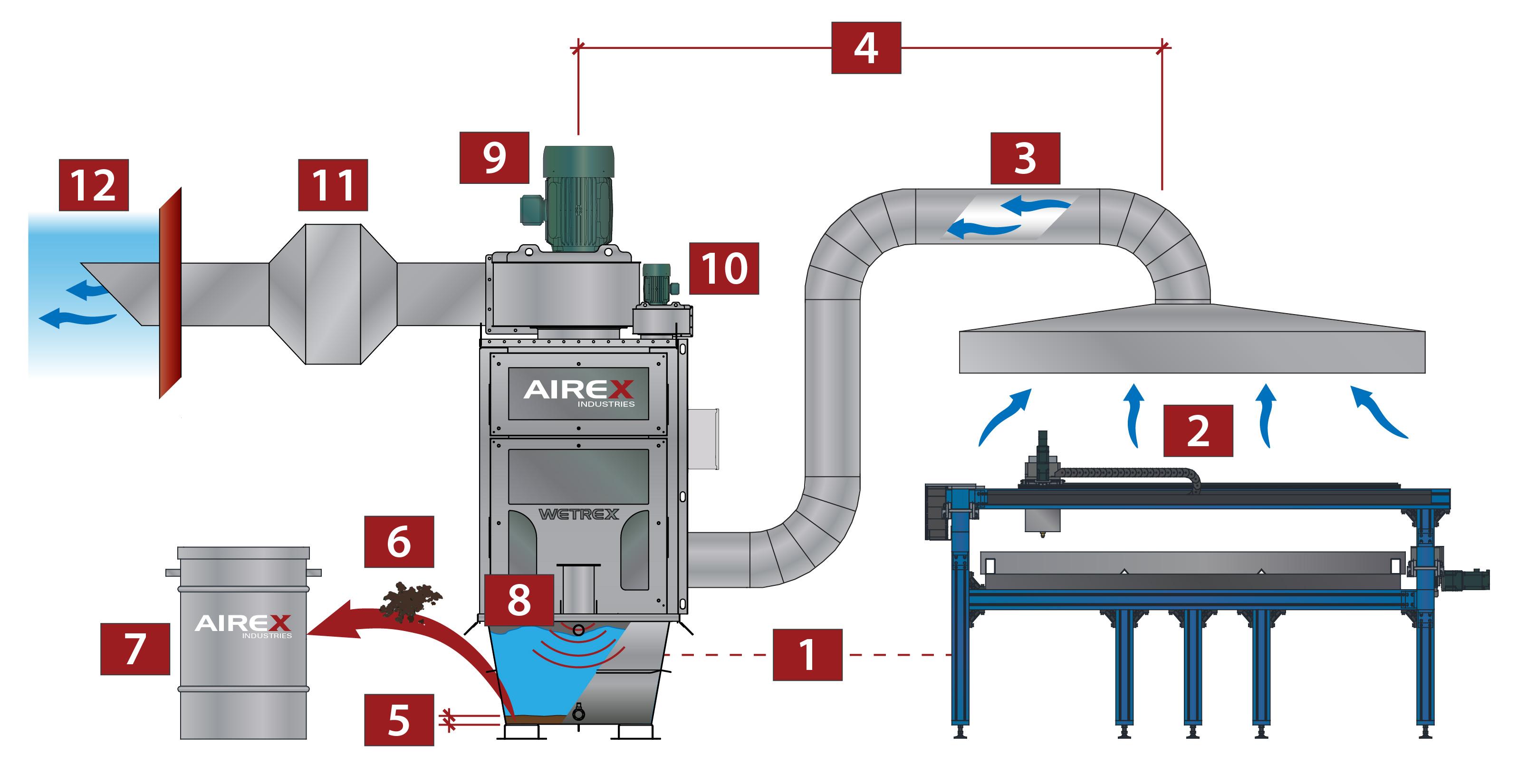

Selecting an appropriate dust collector is not the sole factor to consider. The applicable codes recommend the following criteria to be met for wet dust collection:

1. Interlocked equipment must shut-down unit if there is a malfunction with the wet dust collection systems.

2. Fine metallic particulate accumulation on exposed surfaces must not exceed 3 mm.

Are you aware that:

An explosion may occur when we exceed the particulate minimum explosible concentration (MEC). For most metallic dust, the MEC lies between 30 g/m3 and 190 g/m3.

3. A minimum duct velocity of 4500 ft/min (22.86 m/s) must be maintained at all times in network conduits.

Are you aware that:

Dust may accumulate along conduit surfaces with duct velocities under 4500 ft/min. On the other hand, duct velocities above recommended levels consume energy required to maintain excess velocities with the increased risk of particle erosion of conduit walls.

4. Locate capture inlets and wet dust collector as close as possible to reduce conduit length.

5. Sludge level buildup shall not exceed 5% of the dust collector water tank volume.

6. Sludge shall be removed if the wet dust collector remains inoperative for more than 24h.

7. Sludge container shall not exceed 50 lb.

8. Water level control logic must be maintained, otherwise visual and audio alarm trigger with automatic shut-down of the wet dust collector systems.

9. Blower shall be located on the clean-air side.

10. When the wet dust collector is inoperative, an independent power-suppled blower shall constantly maintain a minimum 10% of the main exhaust fan volume ventilation.

Are you aware that:

Accumulated metal particulate in contact with water, such as within a wet dust collector housing, leads to an exothermic chemical reaction, giving off hydrogen gas. It is imperative that you constantly ventilate the confined area when the unit is inoperative to avoid hydrogen gas explosions.

11. A dry filter could be installed downstream of the wet dust collector if it's equipped with the following safeguards.

- Differential pressure alarm

- Static dissipative filter media

- A means to limit hydrogen accumulation to 10% of the Lower Flammable Limit

- High-temperature alarm at the filter media limit

12. Exhaust vent to a safe location outside the building.

Conclusions:

A wet dust collection unit, such as the Wetrex, requires little maintenance. Instead of replacing filtration media and valves as you would normally perform on a dry dust collection system, you simply need to change tank water periodically and remove metallic residue sludge accumulations in the Wetrex.

Although the Wetrex is simple to install, we recommend that you have work done by professional staff to correctly determine the most suitable model in sync with your network. On many occasions, companies purchase and improvise a makeshift air decontamination equipment installation with inevitable flaws that need to be corrected. Initially set up to save money on their investment, such business practices unfortunately take their toll with no benefit.

To better grasp the fundamentals in the prevention of metallic powder explosions and possible dust collector capture port /network configurations, we suggest you consult the following CNESST publication (french only):

http://www.cnesst.gouv.qc.ca/Publications/200/Documents/DC_200_16279.pdf

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?