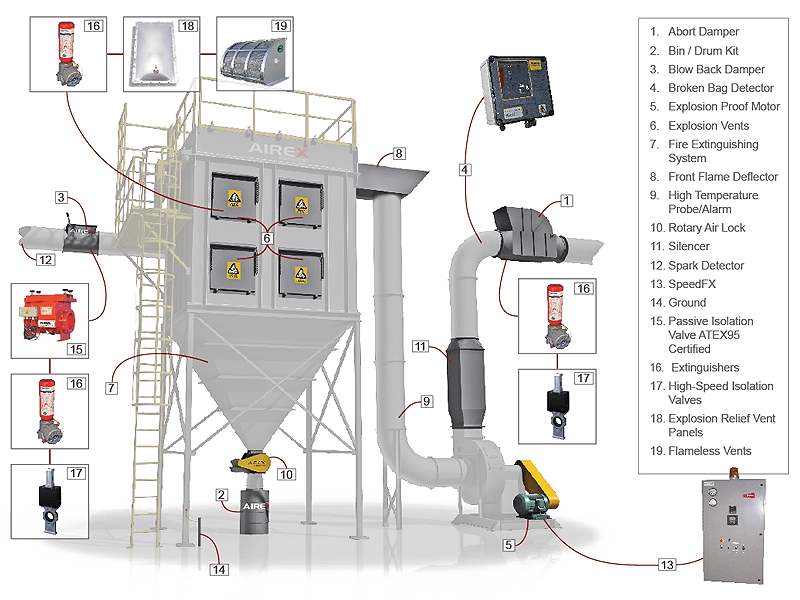

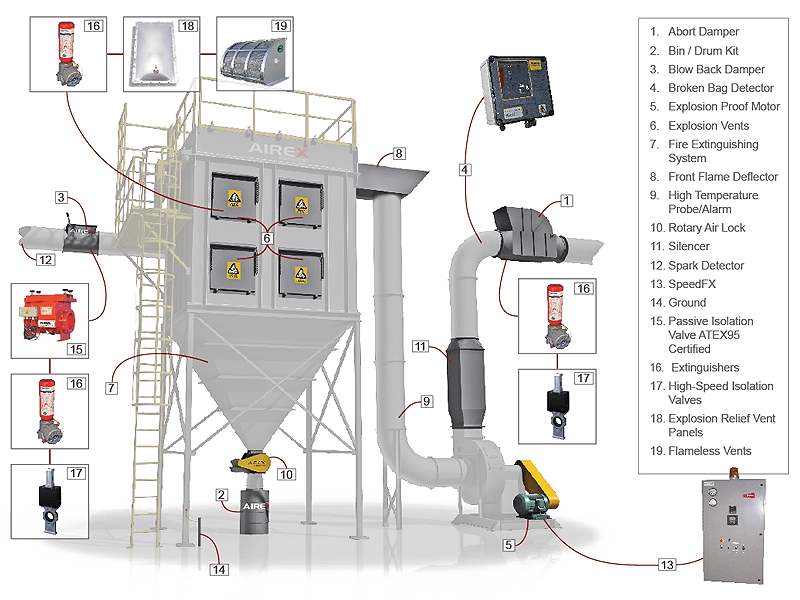

ACCESSORIES

Enhance Your Security and Performance

Some options like the SpeedFXTM can vary motor speed and energy consumption thus improving efficiency.

Airex accessories are designed to meet NFPA regulations, providing effective prevention of fire and explosions while protecting workers and facilities.

Fire Protection Accessories

Abort Damper: Connected with a proper spark or fire detection system, the abort damper redirects exhaust air into the atmosphere as soon as a spark is detected.

Blow Back Damper: The Blow Back Damper ensures there is a seal, should a fire or explosion occur within the dust collector, preventing the return of smoke and fire to the shop via the intake ductwork.

Explosion Vents: The explosion vents redirect a propagating flame or explosion to the atmosphere. Pressure-rated washers are used to seal and release the vents.

Rotary Air Lock: Designed to control the flow of discharge material from a dust collector or other type of process while maintaining an air seal.

Spark Detection & Fire Extinguishing Kit: This system counters the spread of fire with a temperature probe and sprinkler, spraying the collector and stopping the blower (eliminating oxygen intake once a set point is reached).