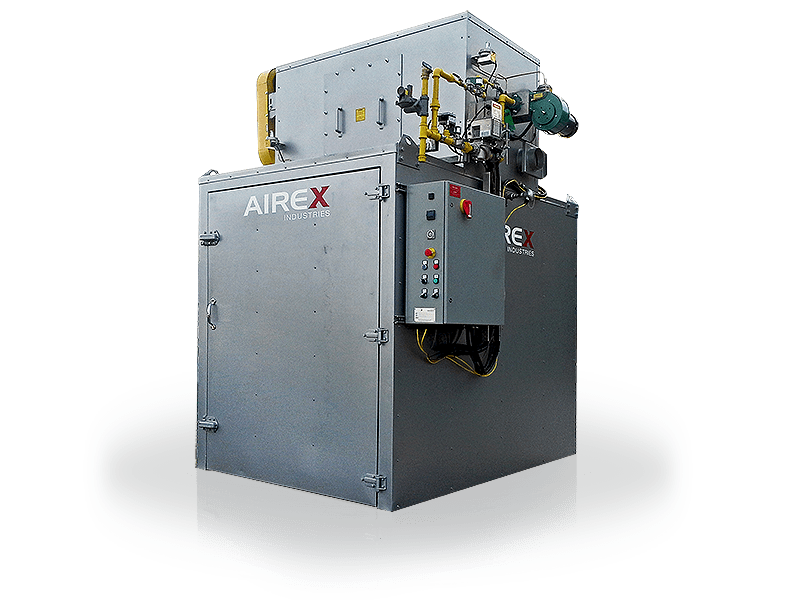

Industrial Oven

FE & FG Series

The industrial oven heated chamber is usually used for a variety of industrial applications such as curing, baking or drying components, parts and/or even final products.

Our industrial oven meet the requirements of NFPA86. They are class B ovens, i.e. they are operating at atmospheric pressure. The industrial oven must not contain any volatile, flammable, or combustible material otherwise additional features must be added in order to meet the requirements for class A ovens.

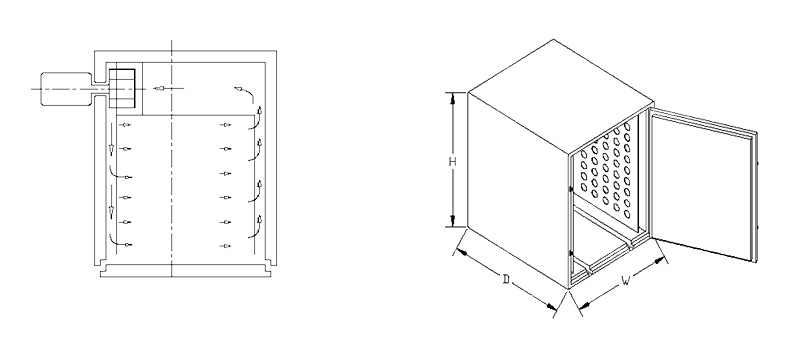

How it Work

When the operator closes the access hatches and switches the industrial oven on, the air within it is heated by a heater. The heated air is then circulated throughout the oven by a fan in order to distribute the temperature as evenly as possible. Once the industrial oven reaches its setpoint, it switches to its minimum output in order to maintain a stable temperature. If necessary a cool off process is initiated by venting the hot air via an exhaust pipe.

OPTIMIZE YOUR INDUSTRIAL DUST COLLECTOR PERFORMANCE

REQUEST AN EXPERT'S OPINION

![]()

Electrical Specifications

Control Panel

- Terminals for incoming power (disconnect not included)

- Temperature controller 1/16 din with Type J Thermocouple

- Heating and ventilation switches

- Pilot Light

- Control panel Nema 1 meeting the CSA requirements

Other

- Operating on 600V, 3-phases, 60Hz

- Completely wired and tested

Optional Features

- Alarm Relay

- Alarm Strobe Light

- Alarm Buzzer

- Open Door Detector

- Circular Chart Recorder

- Digital Daily Time Switch, 7 days 24 hours

- Hour Meter for Blower

- Incoming Disconnect with Fuses

- Control Panel Nema 12

- Temperature Controller1/8 din or ¼ din

- Programmable Temperature Controller

Mechanical Specfications

Blower

- CFM as specified for each model, 2″w.g. @ 70F

- Selected AIREX SXB Model, class 2S

- Backward Inclined

- Shaft Cooler

Insulation

- Mineral Wool ROXUL RHF60

- Maximum Service Temperature of 1200°F

- 4″ Insulation for Walls and Ceiling and 2” Floor Insulation

Paint

- Phosphate Surface Preparation

- Two Polyurethane Coatings

Motor

- High Efficiency TEFC

- Between 1.5 and 10 HP

- 1800 or 3600 RPM depending on model

- OSHA Guards

- V-belts type B

Gasket

- Glass Fibre High Temperature Gasket with Wiremesh Inconel Insert

- Maximum Service Temperature 1000°F

Handles/Hinges

- BRIXON 2PC1

- 3 to 4 Industrial Caliber Hinges

Casing

- External (Painted): Steel ASTM36 20GA

- Internal: Galvanized Steel 18GA

- Internal Reinforcement: Steel ASTM36 18GA

- Reinforcements are placed at Insulation Extremities, i.e. every24”. Truck Wheel Guide

Optional Features

- Additional Features necessary for Class A Ovens

- Power Exhaust

- Explosion Hatch and Venting

- Exhaust Stack

- Thermocouple Guard

- Motor Guard

- Shaft/ Bearing Guard

- Sliding Doors

- Automatic Door Opening Device

Technical Data

| Model |

Maximum |

Dimensions | Heat Input |

Blower | Insulation | ||||

| Interior (H x D x W) |

Working Space (pi3) |

Exterior (H x D x W) |

kW (Electrical Oven) |

BTU/hr (Gas Oven) |

CFM | HP | |||

| 644 | 500 | 72"x48"x48" | 96 | 78"x74"x64" | 20 000 | 250 000 | 2083 | 1,5 | 4" |

| 665 | 500 | 72"x72"x60" | 180 | 78"x101"x76" | 30 000 | 300 000 | 2805 | 2 | 4" |

| 685 | 500 | 72"x96"x60" | 240 | 78"x128"x76" | 40 000 | 350 000 | 3570 | 3 | 4" |

| 666 | 500 | 72"x72"x72" | 216 | 78"x104"x88" | 40 000 | 350 000 | 3570 | 3 | 4" |

| 686 | 500 | 72"x96"x72" | 288 | 78"x130"x92" | 60 000 | 400 000 | 5100 | 5 | 4" |

| 6106 | 500 | 72"x120"x72" | 360 | 78"x158"x96" | 60 000 | 600 000 | 6630 | 5 | 4" |

| 6126 | 500 | 72"x144"x72" | 432 | 78"x182"x100" | 90 000 | 600 000 | 8500 | 7,5 | 4" |

| 886 | 500 | 96"x96"x72" | 384 | 102"x134"x92" | 60 000 | 600 000 | 6630 | 5 | 4" |

| 787 | 500 | 84"x96"x84" | 392 | 90"x134"x104" | 60 000 | 600 000 | 6630 | 5 | 4" |

| 7107 | 500 | 84"x120"x84" | 490 | 90"x158"x108" | 90 000 | 600 000 | 8500 | 7,5 | 4" |

| 7127 | 500 | 84"x144"x84" | 588 | 90"x184"x112" | 120 000 | 700 000 | 10625 | 7,5 | 4" |

| 8108 | 500 | 96"x120"x96" | 640 | 102"x160"x120" | 120 000 | 800 000 | 10625 | 7,5 | 4" |

| 8128 | 500 | 96"x144"x96" | 768 | 102"x195"x124" | 150 000 | 1 200 000 | 14875 | 10 | 4" |

CONTACT OUR EXPERTS

1-800-263-2303

![]()

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?

Not sure what product fits your needs, or you looking for advice about the best solution for your problem?